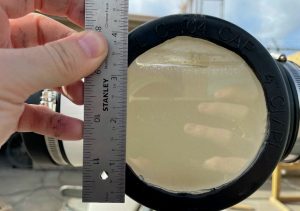

Sulphur run-down lines are typically sized by referencing past projects and ‘rules of thumb’. Very little analysis is performed to identify the impacts of slope, fittings, valves, etc. It is critical to maintain an open vapour path from the condenser to the sealing device. CSI has observed problems in the field which appear to be caused by undersized run-down lines. CSI developed a method of predicting the liquid level in a run-down line that considers the most common elements. This was accomplished by building a full-scale model of a run-down line that evaluated pipe NPS, pipe slope, rod-out-cross elbows, rod-out cross elevation drops, and liquid viscosity. This article* presents the testing and development of the predictive method as well as the predictive method itself.