Sustainable refineries

Liquid fuels will be with us for decades to come, but refiners will be pushed to decarbonise their activities, via greater use of biofuels, and green/blue hydrogen use.

Liquid fuels will be with us for decades to come, but refiners will be pushed to decarbonise their activities, via greater use of biofuels, and green/blue hydrogen use.

Market Insight courtesy of Argus Media. Urea: Prices fell in most global markets in early March as suppliers chased limited demand. Although India’s purchase tender has yet to formally conclude, IPL looks set to book 1.15 million tonnes of urea at $330-334.8/t cfr, with traders mainly sourcing from Russian and Middle Eastern producers.

Sulphur is a vital secondary crop nutrient. It can be delivered in sulphate, thiosulphate and elemental form. The range of product and process options are outlined.

Suncor has selected Rich Kruger to be the company’s next president and CEO, effective from April 3rd, according to the company. Kruger will also join the Suncor board of directors. The announcement follows a search process conducted by a special committee of the board. Rich Kruger previously worked for ExxonMobil for 39 years, and was the chairman and CEO of Imperial Oil Ltd from 2013 through 2019 before retiring from the company, where he focused on safety, reliability and operational excellence. Kris Smith, who has been interim CEO since July 2022, will work with Kruger to ensure a smooth transition before assuming the role of Chief Financial Officer and Executive Vice President of Corporate Development, at the conclusion of Suncor’s annual general meeting on May 9, 2023. Alister Cowan, the current CFO, plans to retire but has offered to remain with the company through the end of the year to support the transition to Mr. Smith and to provide advisory services. Smith replaced previous CEO Mark Little, who resigned in July 2022 following investor pressure after a series of safety incidents and fatalities.

Lithium sulphur batteries have many advantages over conventional lithium ion batteries in terms of energy density, and they also avoid the use of costly cobalt, but they deteriorate rapidly and cannot be recharged as frequently. However, recent advances in Li-S batteries could overcome this problem and lead to widespread adoption.

Most processes involving sulphur, from smelting to refining, produce sulphur dioxide as a by-product. Regulations continue to tighten on industrial SO2 emissions worldwide, leading to greater recovery of sulphur and sulphuric acid at these sites.

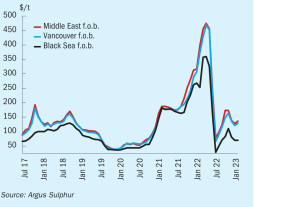

Meena Chauhan , Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

CRU, a leader in sulphur industry market analysis, price assessments, consultancy and events, and Abu Dhabi-based UniverSUL Consulting LLC, dedicated to providing unbiased technical expertise in sour hydrocarbon production and sulphur recovery, have announced a formal partnership aimed at enhancing the value of industry events for the sulphur industry.

As it is an involuntary product, sulphur tends to be sold at whatever price the producer can get for it. This means that one of the major determinants of the sulphur price is the cost of transporting it to the customer, and in this regard one of the key indices is the Baltic Dry Index (BDI), which measures the cost of shipping dry bulk goods around the world, reported daily by the Baltic Exchange in London. The BDI has been on quite an excursion over the past couple of years – perhaps not as wild as the period from 2004-2009 when everyone wanted to ship goods to and from China, there was a shortage of vessels to carry it, and oil prices were at record highs - but eye-catching nevertheless.

China has been the major market for base metals, including copper, nickel, lead and zinc over the past two decades as the country rapidly industrialised. But with China’s growth slowing due to demographics and market saturation, where are metals markets and production of/demand for sulphuric acid likely to go next?