Market Insight

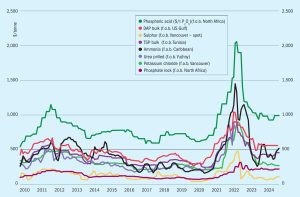

Market snapshot, 17th October 2024 Urea : Prices firmed in a thin market in mid-October. Middle East values shot up $20/t on expectations that Indian Potash Limited (IPL) would announce another tender to secure tonnes for India in December. If correct, this will follow hot on the heels of the latest Rashtriya Chemicals and Fertilizers (RCF) purchase tender for 0.56 million tonnes of urea. Sohar International Urea & Chemical Industries (SIUCI) sold a November cargo at $390/t f.o.b. with further trader interest reported at $385/t f.o.b. This demand was probably generated by traders positioning themselves for IPL’s expected tender, given that other markets generally remained quiet.