Market Insight

Market Insight courtesy of Argus Media

Market Insight courtesy of Argus Media

We highlight recent advances in ammonia and dust scrubbing systems for urea plants from Stamicarbon, thyssenkrupp Industrial Solutions and Toyo Engineering Corporation.

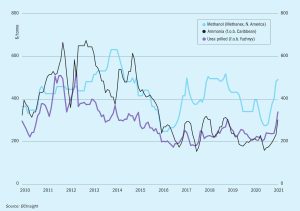

The ammonia industry faced a difficult February, due to extremely cold weather conditions in the northern hemisphere. In the US, production outages resulting from winter storm Uri affected up to 7 million t/a of capacity.

Market Insight courtesy of Argus Media

Copenhagen Infrastructure Partners (CIP) has unveiled plans to build Europe’s largest power-to-ammonia facility at the Danish port of Esbjerg, based on electricity from offshore wind turbines. The company said the plant will consist of 1GW of electrolysis capacity, capable of supplying sufficient hydrogen to produce 300,000 t/a of ammonia, and that the ammonia will be used as both as agricultural fertiliser and as fuel for the shipping industry. Excess heat generated in the process would be used to provide heating for around one third of local households in communities around the plant, to be sited on the west coast of Denmark. The company has signed a memorandum of understanding for the project with companies from both the agriculture and shipping sectors, including Danish Crown, Arla, DLG, Maersk and DFDS Seaways. CIP anticipates that it would cost approximately $1.2 billion to build the facility. They are currently seeking investors for the project and expect that the investment decision would be reached by 2023. The plant could enter commercial operations in 2026.

As the Covid-19 pandemic continues, we look ahead at fertilizer industry prospects for the next 12 months, including the key economic and agricultural drivers likely to shape the market during 2021.

Market Insight courtesy of Argus Media

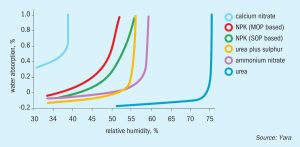

The quality of finished fertilizers can be maintained during transport, handling and storage by protecting the surfaces of granules and prills with coating agents. We survey the range of anti-caking, water repellent and anti-dusting additives currently on the market.

The year 2020 will be remembered as an uncertain, demanding and challenging year. When faced with a global pandemic, companies have adopted new approaches and remote inspection, monitoring and training using the latest digital tools has been key for the successful completion of projects. Stamicarbon, Casale and KBR share some of their experiences of the past year.

The following case studies describe serious incidents associated with leak detection system failures. Incident 4 relates to the failure of the active pressurised leak detection system for the loose liner of a urea reactor and Incident 5 relates to a passive leak detection system which failed to work leading to serious corrosion of the carbon steel wall of the HP scrubber.