Market Insight

Market Insight courtesy of Argus Media

Market Insight courtesy of Argus Media

Like the vital nitrogen fertilizer they handle, seasonal cheer will be in short supply for Europe’s ammonia producers and buyers this festive season, after many difficult months in which upward price trajectories showed no sign of slowing.

Improvements to nutrient use efficiency (NUE), particularly for nitrogen, can deliver dual environmental and economic benefits. We report on recent developments in nitrogen management and global progress on NUE.

The feed phosphates industry is caught between conflicting trends currently, according to Alberto Persona of the Fertecon fertilizer team at IHS Markit. While the long-term demand-side fundamentals look broadly stable, there is still likely to be a fight for market share due to competition from substitute products and the emergence of new projects.

More than 230 delegates from 45 countries participated in CRU’s Sustainable Fertilizer Production Technology Forum, 20-23 September 2021. To highlight this successful virtual event, we report on keynote and selected technical presentations.

ACI will convene the 5th European Mineral Fertilizer Summit in London on 1-2 December 2021. Fertilizer International is proud to be a partner for this year’s event.

Rapidly escalating natural gas prices forced plant closures across Europe during September. Worst affected was the UK, where a fire at a cross-Channel electricity cable and low output from wind energy has, combined with low domestic storage capacity led to a surge in demand for gas for power stations and wholesale gas prices reached a record 350 pence per therm (equivalent to $46/ MMBtu) in October. On September 15th, CF Industries announced that it was halting operations at both its Billingham and Ince fertilizer plans due to high gas prices. Although ammonia prices have also risen, they have not kept pace with gas price rises, and there is a limit to what farmers could be expected to pay. CF CEO Anthony Will said: “$900 is the gas cost in a tonne of ammonia and the last trade in the ammonia market that was done was $700 a tonne”. As these plants supply most of the UK’s carbon dioxide for food and drink manufacture, the government said it would provide “limited financial support” to keep the Billingham plant operational, and that plant re-started on September 21st. Meanwhile, BASF closed its Antwerp and Ludwigshafen plants in Belgium and Germany due to what the company called “extremely challenging” economics. Fertiberia ceased production at its Palos de la Frontera site in Spain, and Puertellano remained down for scheduled maintenance. Yara shut 40% of its European ammonia production in September, and OCI partially closed its Geleen plant in the Netherlands. Achema in Lithuania decided against restarting its ammonia plant following maintenance in August, and OPZ in Ukraine shut one ammonia line at Odessa, with Ostchem and DniproAzot likely to follow. Borealis in Austria also reduced production.

Every urea plant continuously fights again corrosion. The intermediate product ammonium carbamate is extremely corrosive under synthesis conditions. The applied materials of construction require oxygen to form a protective passive layer of chromium oxides. The ammonium carbamate solution will continuously dissolve the passive layer, therefore it is vital to continuously supply oxygen, typically in the form of air, to maintain the passive layer. During blocking-in conditions of the synthesis section it is not possible to add air and the oxygen present will be consumed as a result of the passive corrosion reactions, while at the same time the passive layer dissolves in the ammonium-carbamate solution. At a certain point, the oxygen content in the solution becomes too low to assure a passive layer. At that moment active corrosion will start with much higher corrosion rates than passive corrosion. The picture on the left side shows the passive layer (blue, brown, grey surface) and the picture on the right side shows active corrosion (a shiny silver surface). It is important to realise that once active corrosion starts it cannot be stopped, adding more oxygen at this stage, for example, will not work. Active corrosion will continue, leading to the risk that the protective layer will be severely damaged. The only way to solve this situation is to drain the synthesis section and re-passivate the surfaces.

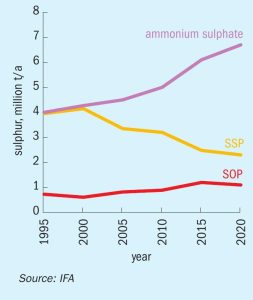

Sulphur is becoming an increasingly important crop nutrient, due to a combination of lower airborne sulphur emissions, the increasing prevalence of high analysis fertilizers, and higher cropping intensities.

An update on the latest in fertilizer ship loading, handling, bagging and blending, including new contracts, company news and advances in technology.