Sulphur 390 Sept-Oct 2020

30 September 2020

New self-cleaning sulphur strainer

SULPHUR FILTRATION

New self-cleaning sulphur strainer

For the protection of nozzles in sulphur forming plants it is important to prevent larger particles from entering the forming machinery and possibly blocking the nozzles. In normal operation, pipeline strainers are used. Sulphurnet has designed a new system which is suitable for continuous or batch operations and has lower maintenance costs. J. Hermans of Sulphurnet introduces the self-cleaning sulphur strainer.

Process filtration may give the impression of being an easy step, but today’s demanding requirements for high filtration quality, automation and reduction of operational and investment costs makes filtration a field for special study.

Over the years, strainers have been placed in-line with process piping to remove large solid contaminants from the flow. A wide variety of filter materials can be used to achieve the required product quality. The most frequently used filter materials are perforated screens, screens covered with filtration mesh and wedge edge filter elements. However, pipeline strainers have a limited filtration area and have high maintenance costs, which calls for a review of this filtration process.

Environmental considerations such as emissions and safety in the workplace also play an important role in the decision for new investments, since manual cleaning of strainers is becoming less acceptable. All of these factors influence production targets, customer satisfaction and companies’ profits.

Sulphurnet has designed a system, called a Self-Cleaning Sulphur Strainer which is suitable for continuous, as well as batch-operations, has low maintenance costs and takes into account the criteria mentioned above.

Strainer function

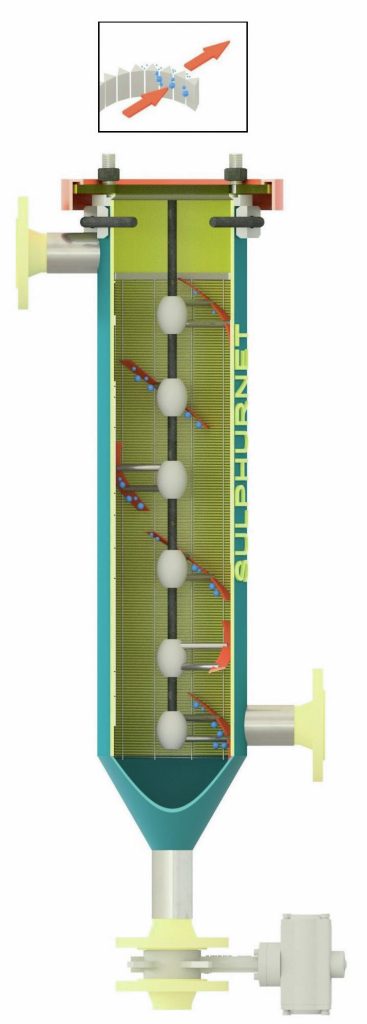

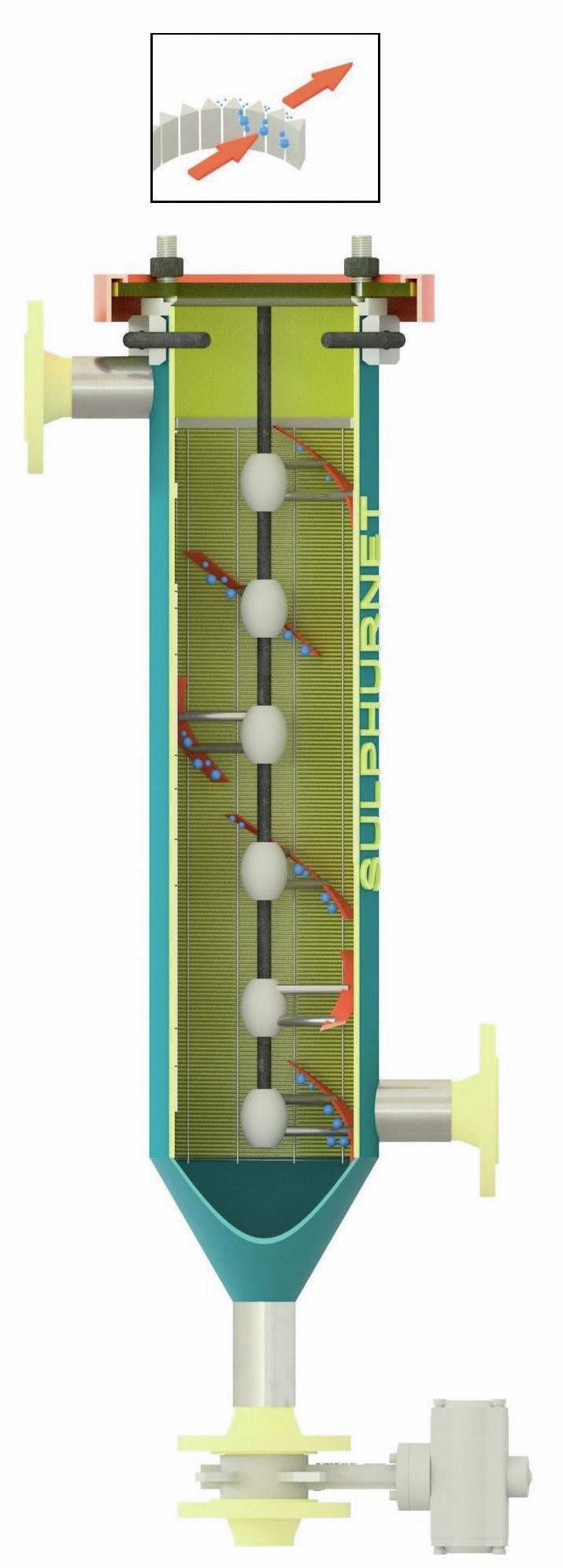

The heart of the Self-Cleaning Sulphur Strainer is an asymmetric edge-gap strainer element located centrally in a pressure vessel. The liquid flow is from the inside of the edge-gap strainer to the outside, keeping the particles on the inside. For cleaning purposes the strainer has a rotating axis with various impellor blades which rotates inside the strainer to remove the collected debris.

The edge-gap strainer is totally cleaned due to the particular design and rotation of the impellor. The impurities are pushed downwards and accumulate in the concentration chamber. After a pre-set number of cleaning cycles the solids are discharged by means of a drain valve in the bottom of the filter.

The filtered liquid leaves the filter through a side outlet. The filter housing is only in contact with the filtered liquid. The filtration, cleaning and the concentrate discharge cycles are carried out continuously, and are sequenced by a PLC.

The cleaning cycle is carried out by an electrical motor which is activated either by a pre-set pressure differential or by running on time valves; alternatively the operations can run continuously.

The frequency of operation of the drain valve is set by the number of cleaning cycles or time regulated.

The opening time of the drain valve can be set as required. This means a maximum concentration of solids can be achieved which results in a minimal loss of product. During the cleaning cycle filtration continues, which means that the process is not interrupted.

Edge-gap strainer

The Self-Cleaning Sulphur Strainer filter utilises an edge-gap strainer which is specially machined on the inside so that solid particles cannot attach to it. The rotating agitator knives scrape the impurities from the filter-element which means that the flow is uninterrupted.

The use of edge gap strainer offers the following advantages:

- high mechanical strength;

- self-supporting structure;

- retention from 50 micron and above;

- relatively high open area;

- non plugging surface;

- low maintenance cost;

- low operational cost.

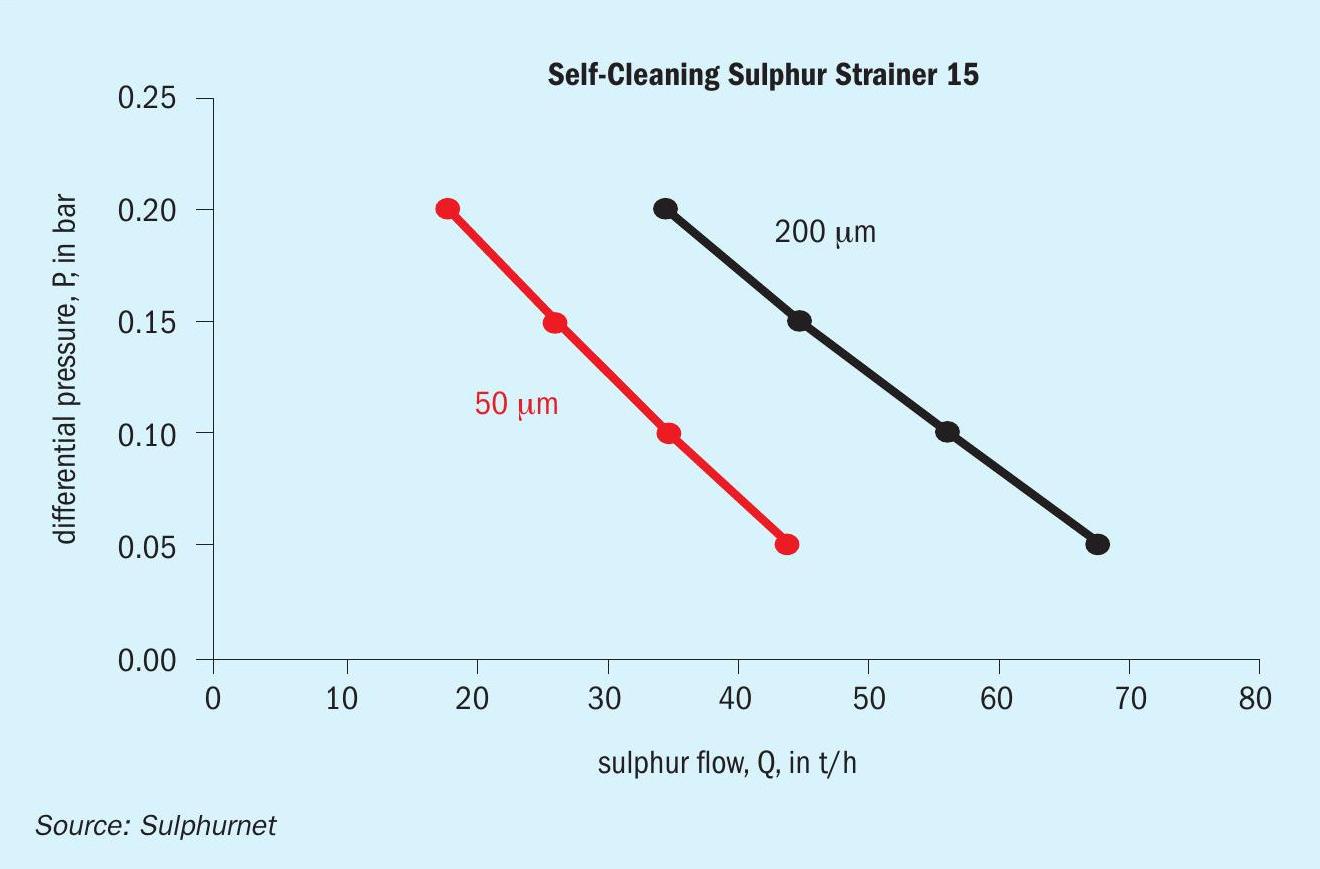

Due to the continuous cleaning cycle, a low-pressure differential is achieved which results in a constant flowrate. The flow characteristics of the Self-Cleaning Sulphur Strainer are shown in Fig. 1.

In current practice, two pipeline-strainers are typically installed, with one in operation and the other one in a cleaning cycle or in standby position. These strainers have to be cleaned manually which is not only time consuming, but also a hazardous operation; spilling of hot sulphur can cause severe burn wounds.

Cleaning of the strainer basket is also difficult, carsul and the solidified sulphur are hard to remove from the strainer basket and in most cases it should be replaced.

The Self-Cleaning Sulphur Strainer operates continuously, even during the cleaning cycle. The system is fully jacketed so the internals are kept at the correct temperature to ensure sulphur remains in liquid form.

The lack of clarity in the filtration market makes it difficult to decide on the best solution for a given application. Before making the selection it is important to carry out a thorough evaluation of costs, both operational and investment, and to take into account both process conditions and environmental issues.

The unique Self-Cleaning Sulphur Strainer is an efficient filter system for filtration tasks in sulphur processing, fulfilling stringent requirements.

Typical application

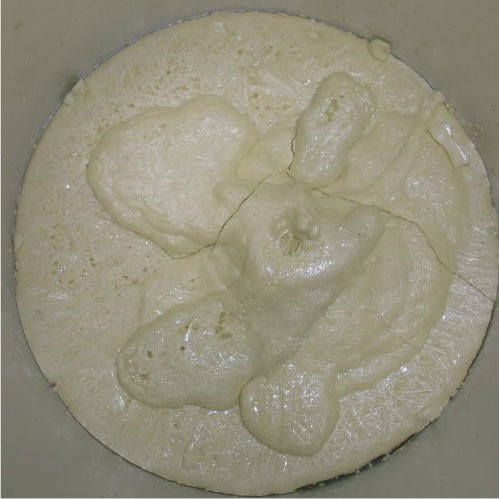

Elemental sulphur produced by the Claus process contains both physically dissolved H2 S and chemically bound H2 S in the form of hydrogen polysulphides. The principle of sulphur degassing is the removal of the dissolved H2 S from the liquid sulphur. Degassing is carried out as a batch or continuous process in the dedicated pit. The actual degassing takes place by bubbling air through the liquid sulphur. The SS air nozzles ae subject to corrosion and particles are released in the liquid sulphur. These particle need to be removed before sulphur forming.

Laboratory tests showed the required retention to obtain a clean sulphur product. Two options were possible, stop the process and repair the air nozzles, or install a self-cleaning strainer. The self-cleaning option was selected and successfully installed.