Sulphur 401 Jul-Aug 2022

31 July 2022

Simple tests to keep problems at bay

PLANT MAINTENANCE

Simple tests to keep problems at bay

E. Almeida and B. Ferraro of Clark Solutions discuss how regular monitoring by simple testing of the towers in sulphuric acid plants can improve the reliability and lifespan of the plant.

Planning and strategy are imperative for an efficient sulphuric acid plant maintenance shutdown. Often, the need to substitute tower internals is only perceived when the status is critical, when abrupt process oscillations occur, or only at the moment the tower is opened.

Being in such a situation causes delays in downtime, requires urgent decision making and the selection of stop gap solutions and, in the worst-case scenario, production is stopped until the damaged item has been manufactured.

Predicting when tower internals need to be substituted is extremely important to enhance plant reliability and lifespan and can be determined by simple tests if executed in a frequent and correct manner, providing enough time to decide between a repair or acquisition of a new piece of equipment.

Simple tests

A wide range of tests can be executed to evaluate the health of a sulphuric acid plant. Clark Solutions believe three of the most basic and practical tests are:

- dew point at the drying tower;

- Kitasato test at the absorption tower;

- stick test at the drying and absorption towers.

These tests can be performed weekly or monthly requiring minimal resources.

The tests reveal relevant information which can be used to infer weak points in the plant. The results indicate which equipment demands attention in the next scheduled shutdown.

As a disclaimer, test descriptions in this article are for illustrative purposes. It is highly important that tests are performed safely and reliably, following all protocols for execution, and with all personnel wearing all necessary personal protective equipment.

Dew point test

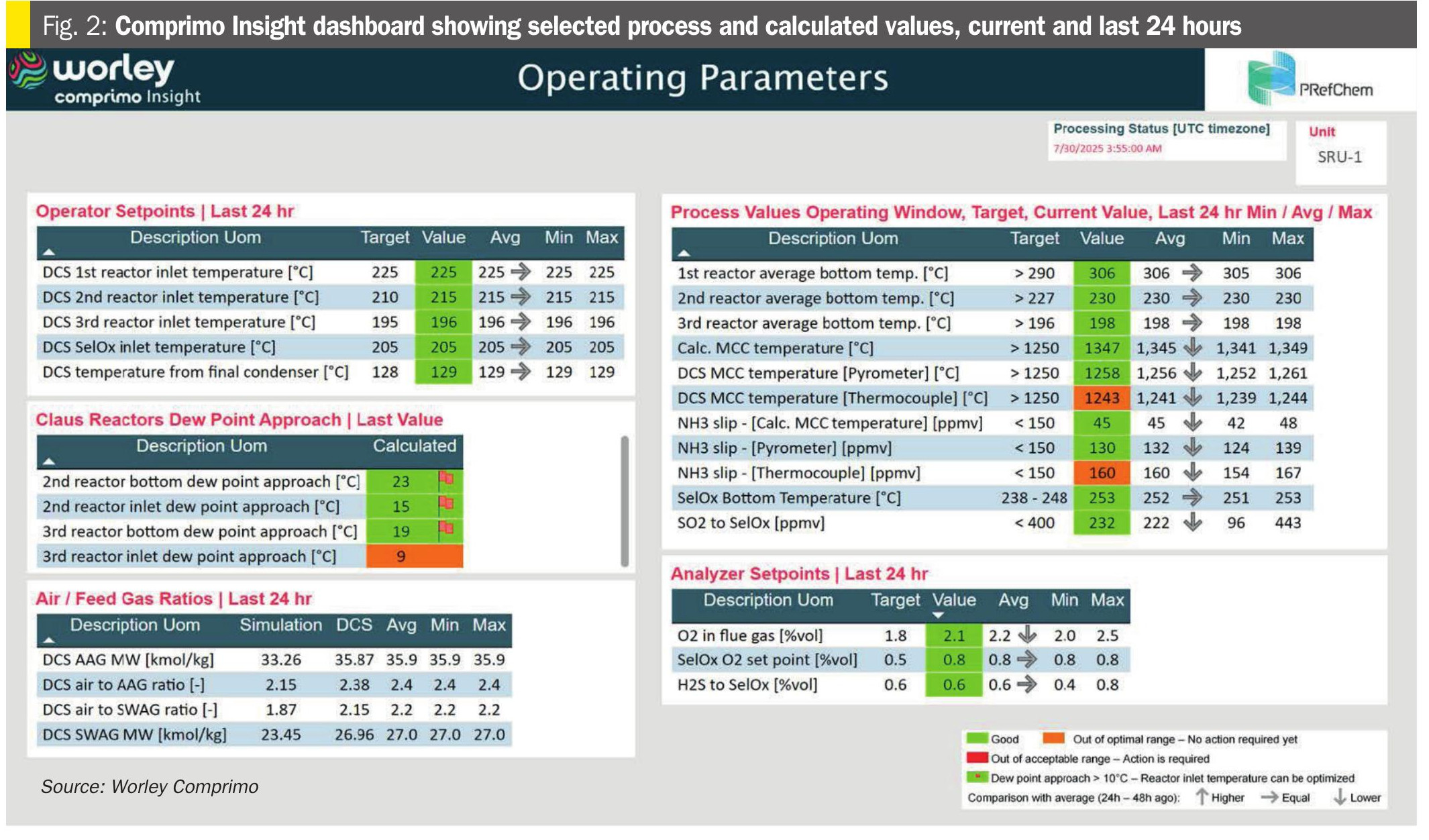

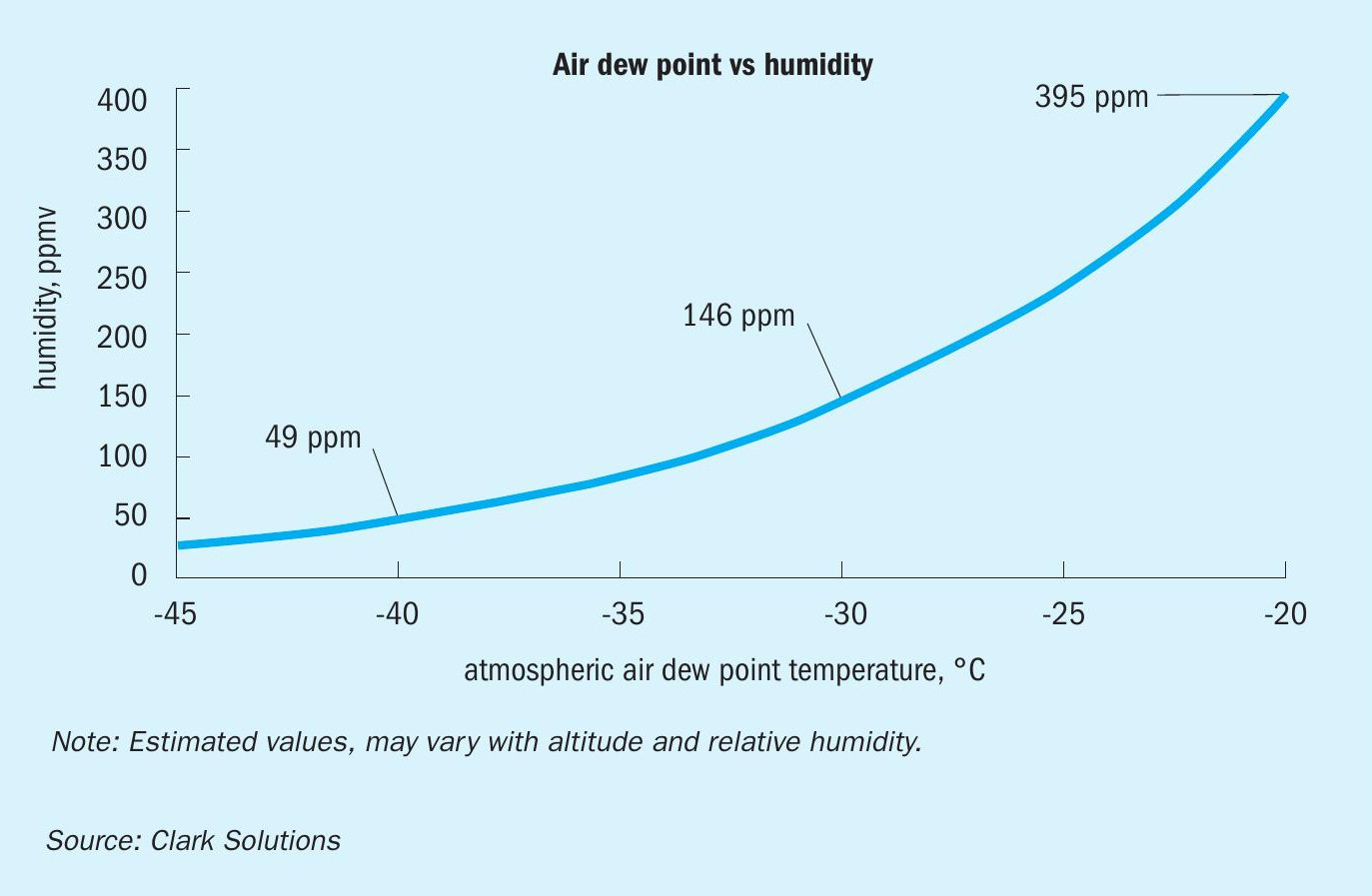

The dew point test indicates the health of internals and operation in drying towers. It shows the tower drying capacity in a quantitative manner (usually precise to within 2 to 3°C). The test measures the dew point of the outlet gas stream. With this value, it is possible to estimate the remaining water concentration (Fig. 1) of the gas stream.

A dew point test can be easily performed in a Lectrodryer device or similar, as illustrated in Fig. 2. While feeding dry gas to the device, using the tower’s positive pressure or with the support of a vacuum pump in negative pressure towers, dry ice and acetone are placed on the inner side of the device’s polished cup, together with a thermometer. As the acetone and dry ice evaporate, heat is removed from the mixture and the temperature drops continuously. As it decreases, the polished cup outer surface cools down. As the temperature decreases, one must observe the sight glass and the cup outer surface. When the smallest trace of condensation is observed, the dew point temperature displayed on the thermometer is registered.

A dew point of around -40°C is an indication of very good air dryness. Dew points above -30°C are cause for concern, particularly on plants with low temperature economisers and other low tube wall temperature devices.

Evaluation of tests results are better described in Clark Solutions’ article in Sulphur no. 396 pp. 38-41 (Sep-Oct 2021). Summing up, high dew point could reveal issues such as: insufficient acid irrigation (by distributor or circulating flowrate), inadequate irrigation temperature, packing preferential paths and more.

Tower internals such as ceramic saddles e.g., MaxiSaddle® and liquid distributors e.g., Maxiflow® could assist in providing better operation.

Kitasato test

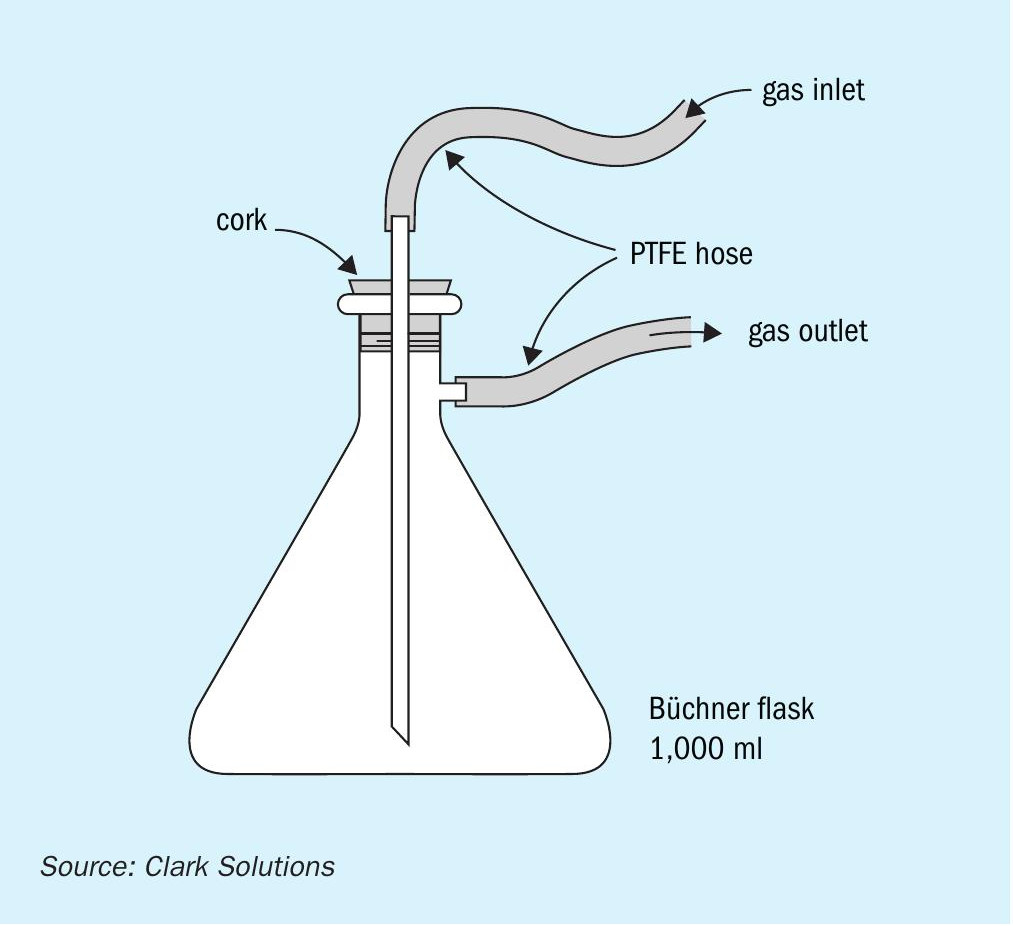

The Kitasato test (Fig. 4) indicates the health of the internals and operation in absorption towers. It shows humidity, sulphuric acid entrainment and/or SO3 presence in a qualitative manner.

The visual results are listed below and are referred by number later on:

1. Whiteish gas formation in the flask interior as well as deposition of sulphuric acid droplets at the flask bottom may indicate the presence of humidity (Fig. 5).

2. White smoke formation at the PTFE hose outlet (outside the flask) may indicate SO3 in the gas.

3. Sulphuric acid deposition inside the flask may indicate sulphuric acid entrainment.

4. No smoke formation nor liquid accumulation inside the flask is also possible.

The test can be carried out with a Büchner flask (also known as Kitasato), cork and PTFE hose, as shown in Fig. 4. It is mainly applied in two typical positions: between the converter and the absorption tower and the absorption tower outlet, bringing different interpretations of the results.

The presence of humidity is often evaluated between the converter and the absorption tower, where a gas with SO3 and negligible water content is expected. If the plant is performing accordingly, only result 2 is observed, since the SO3 in the gas stream goes through the flask and only reacts with atmospheric humidity when it leaves the system, generating a sulphuric acid fine mist that is perceived as a white smoke. On the other hand, if the humidity is higher than expected, results 1 and 2 will occur when the gas passes through the flask, since the temperature is decreased, sulphuric acid condensation occurs generating the whiteish gas inside the Kitasato as well as the sulphuric acid droplets condensate at the bottom. The remaining SO3 will pass through the system generating the white smoke at the hose end. The source of the humidity issues could be poor drying or a water leak in heat exchangers, such as boilers, economisers or superheaters.

The presence of SO3 and sulphuric acid entrainment are often evaluated at the absorption tower outlet, where the gas is expected to contain no SO3 , humidity or sulphuric acid entrainment, therefore, result 4 should be observed. If result 2 is observed, it may indicate absorption issues. Also, if result 3 is observed, it may indicate mist elimination problems.

A thorough inspection of the tower internals should be performed, evaluating uneven acid distribution, packing fouling with sulphate, tower gas velocity, plugging of downcomers, leaks and more if result 2 occurs. In case of result 3, empty seal cups, corrosion or plugging of drainpipes, warping or corrosion of the tubesheet, or gasket leak, amongst others may be the cause.

Stick test

The stick test indicates the health of the mist eliminators in the drying and absorption towers in a qualitative manner.

The test consists of inserting a wooden stick (preferably a bright coloured wood) using a nozzle that allows direct contact of the stick with the gas leaving the tower, downstream of the mist eliminators. Ideally it should be executed in a straight tube section at the tower outlet or at the vessel itself, but at a distance sufficient to guarantee good distribution of the gas flow. Clark recommends an exposure time of 30 to 60 seconds.

Any sulphuric acid particles that contact the stick will leave a dark spot on the surface of the wood; the type of spots and distribution may give some indication of the sources. It is important to take pictures of the stick before and after the test to compare what new spots have formed and what are natural wood stains.

Some possible results are listed below:

1. A stick that is completely clean or with few scattered spots indicates a perfect or great result.

2. A high number of scattered small spots indicate mist eliminator issues such as re-entrainment or gas preferential paths.

3. Part of the stick darkening indicates the presence of fine mist (common to absorption towers).

4. Total darkening of the stick indicates high concentrations of SO3 (the non-absorbed SO3 reacts with the residual humidity of the wood).

5. A totally or highly darkened and wet stick indicates a severe issue that must be addressed immediately.

Fig. 6 shows an example for each possible result listed above.

Conclusion

People who visit a doctor frequently to check their health have more chances of identifying a sickness at an early stage and having treatment at a stage that minimises the consequences. Conversely, people who rarely visit a doctor may discover about a sickness too late. The same metaphor can be applied to sulphuric acid plants and the simple tests listed, since they serve as a doctor’s appointment for the tower internals. Being able to notice issues at an early stage may bring some good results which translates into savings and plant safety.

When performing the tests listed for the first time, it is very important to consult with a specialised company, such as Clark Solutions, to gain the complete protocol of execution, not only the concise summary described in this article, granting a valid result and personnel safety. The company may also be able to provide a prognosis from the results and propose some solutions.