Sulphur 403 Nov-Dec 2022

30 November 2022

Mist elimination challenges in corrosive applications

SULPHURIC ACID EQUIPMENT

Mist elimination challenges in corrosive applications

Daniel R. Egger of Sulzer Chemtech Ltd discusses mist elimination challenges in strong sulphuric acid applications and presents the unique Sulzer KnitMesh XCOAT™ mist eliminator as an ideal solution for corrosive services such as in sulphuric acid drying towers.

Droplet removal plays a very crucial role in preventing damage to downstream equipment. This issue becomes more alarming in highly acidic applications such as in sulphuric acid drying towers. Poorly designed, corroded or fouled drying tower mist eliminators are common sources of excessive entrainment. In drying towers, the operating life of mist eliminators is affected by two primary factors: corrosion and fouling. A new high corrosion and temperature resistant fluoroplastic filament used in the Sulzer KnitMesh XCOAT mist eliminator provides an innovative approach to these problems.

Challenges in strong sulphuric acid applications

Proper selection of equipment for mist elimination in sulphuric acid drying and absorption towers is still a challenge from the performance and material points of view. Operating evidence shows that the gas-liquid interface represents one of the highest risks of corrosion and since mist eliminators operate in this region, they are one of the most challenging corrosion environments in the plant. In sulphuric acid drying towers, knitted wire mesh pads are the principal type of equipment used. One of the common sources of excessive entrainment in drying towers is corroded and fouled mist eliminators which causes acid condensation during shutdowns and thus degradation of the catalyst. Several factors have therefore to be considered in the selection of the mist eliminator type and the material of construction where the longevity depends on the operating conditions, acid concentration and material used.

Acid mist eliminators

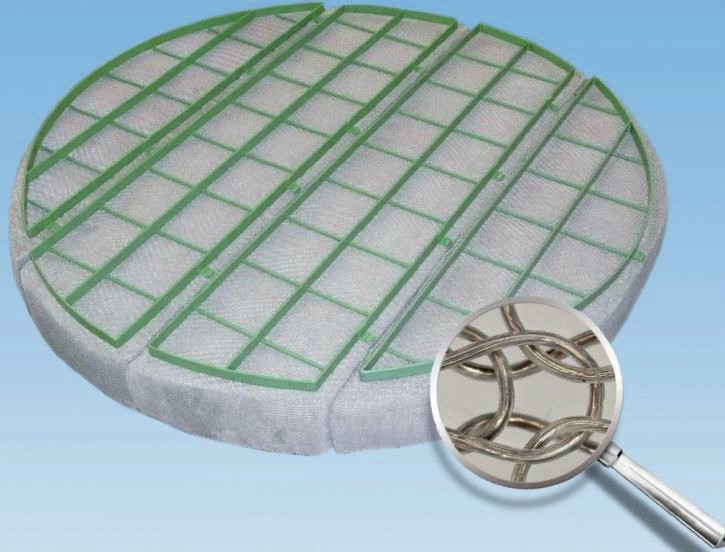

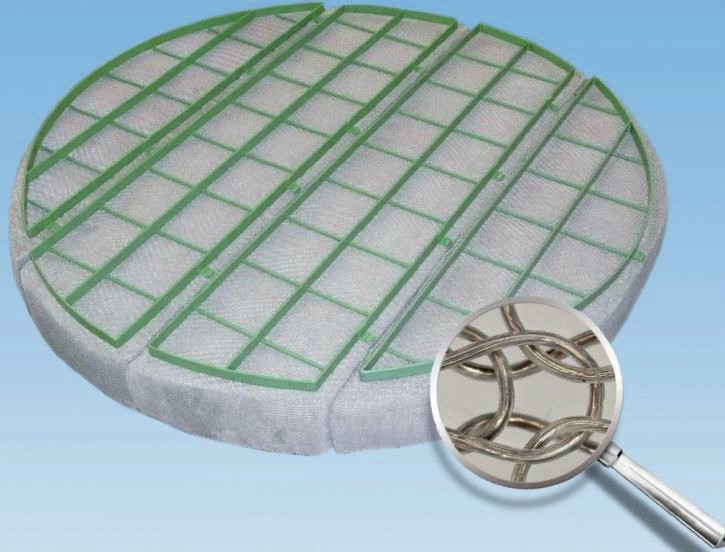

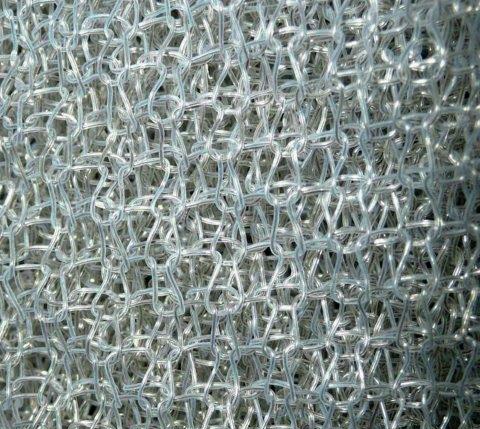

Knitted wire mesh mist eliminators are used as a low cost, highly versatile and efficient method of removing liquid entrainment from gas streams. They are produced as a bed of knitted mesh which presents a tortuous path and large surface area to the droplets entrained in the gas stream. Separation is achieved by impingement and capture by the filaments of the mesh where droplets coalesce and drain. High performance mesh mist eliminators provide excellent separation efficiency down to droplet sizes as small as 2 microns and with a pressure drop typically less than 7 mbar. Fig. 2 provides the grade efficiency for Sulzer KnitMesh XCOAT 9033 and 9798. 100% of the entrainment larger than 2 microns and a significant percentage of droplets below 1 micron diameter are removed.

Impact of corrosion on lifetime

Most common drying tower mist eliminators comprise stainless steel wires which have a standard diameter of 0.28 mm. Even with low corrosion rates, it will not take long for the wires to corrode through.

Assuming a corrosion rate of 0.1 mm/year (4 mpy) the wire will be destroyed in two years or less.

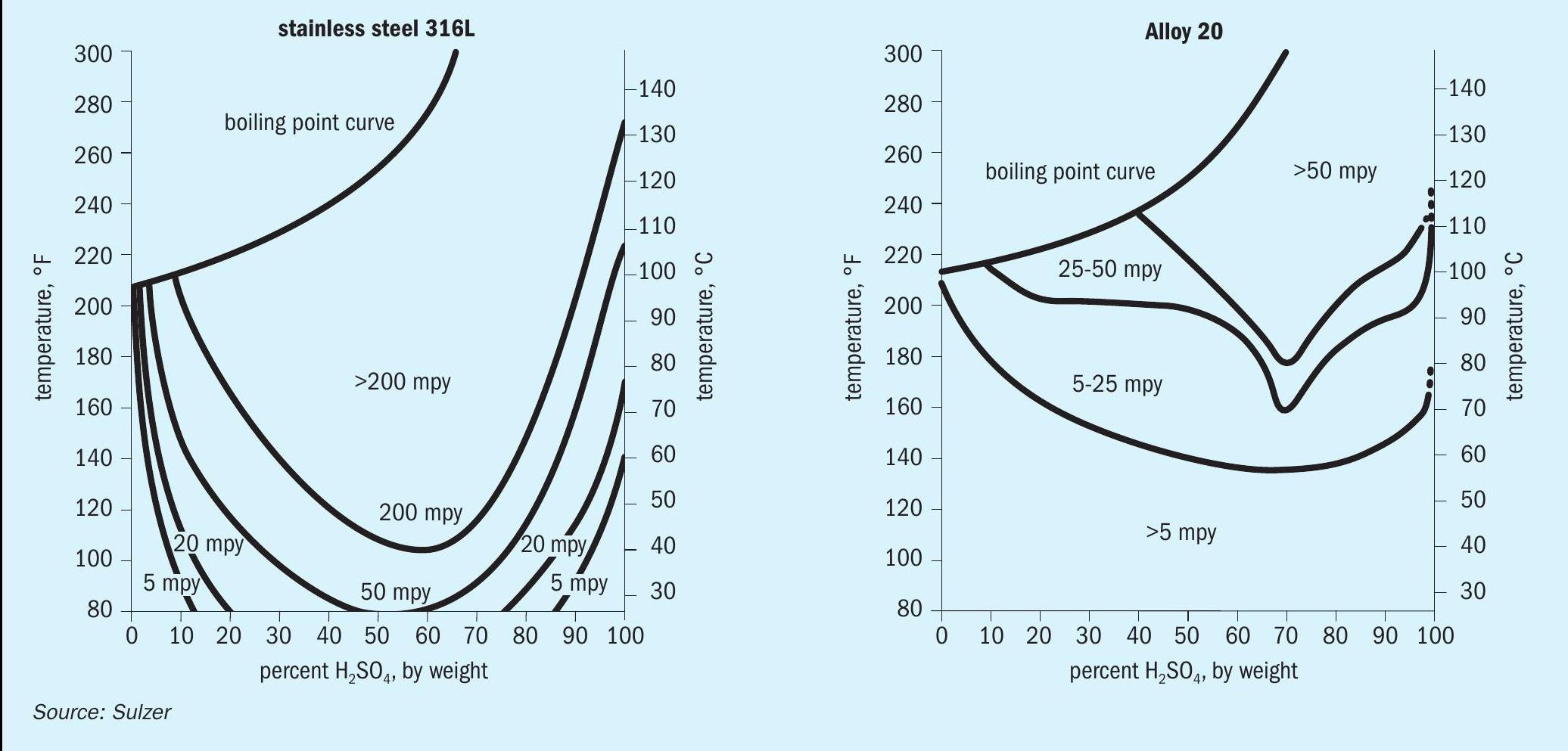

Nickel-based alloys such as Alloy 20 can typically be used to reduce the rate of corrosion and to improve the service life of the mist eliminators (Fig. 3). However, there are cases where even Alloy 20 is not sufficient because the temperature and/or sulphuric acid concentration is in a range where increased corrosion occurs. Drying tower mist eliminators face dangers from such swings in the acid concentration and temperature. Both of these factors can result in a significant decrease of service life.

Silicon-containing stainless steels provide an improved corrosion resistance towards sulphuric acid. But, depending on the alloy type, operating temperature and acid concentration, the corrosion rate can rapidly achieve a critical level for mist eliminator wires where only 0.05 mm of corrosion allowance exists. In addition, the presence of fluorides should be avoided since it will attack the silicon in the alloy.

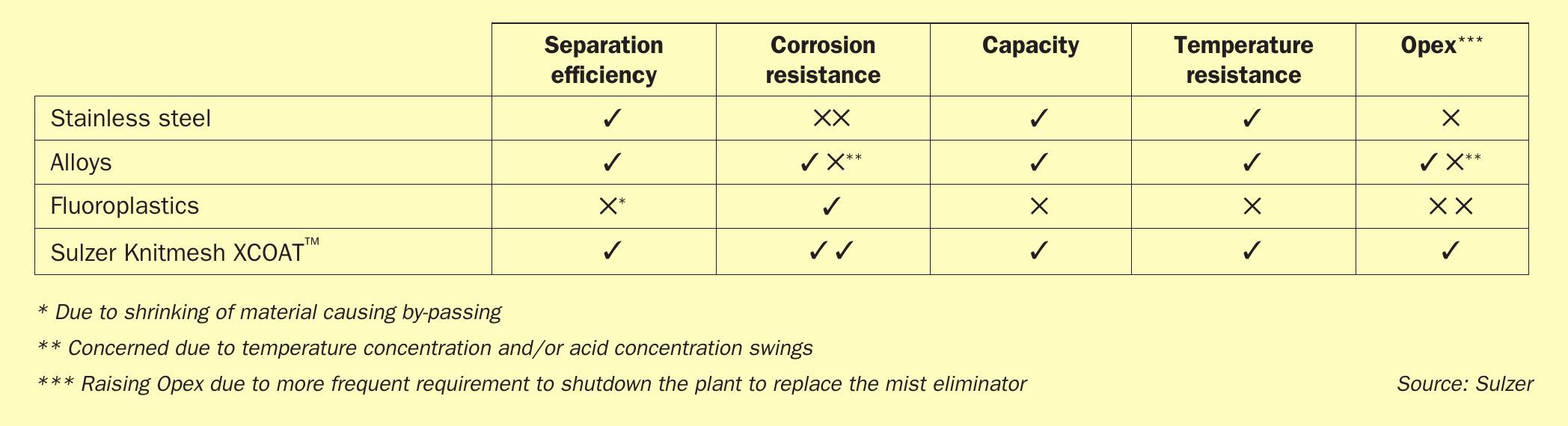

Non-metallic materials such as fluoroplastics like PTFE, PFA, ETFE or FEP are also known to be very resistant to corrosion. However, they lack mechanical strength and are prone to shrinkage at higher temperatures causing gaps between the mist eliminator sections and gas bypassing. Amongst these materials, PTFE and PFA show the best results in resistivity and durability at high temperatures and are totally resistant to sulphuric acid.

Extension of service life with the Sulzer KnitMesh XCOAT mist eliminator

To address these concerns, Sulzer has introduced a new mist elimination solution for corrosive media. The concerns related to corrosion, shrinkage, collapsing is sustainably solved by the Sulzer KnitMesh XCOAT mist eliminator which combines the excellent chemical and temperature resistance of fluoroplastics with the mechanical strength of a stainless steel wire. The Sulzer XCOAT material consists of a 100% pure best-class fluoroplastic monofilament which contains a stainless steel wire core. This leads to extremely high resistance to deformation, corrosion and temperature, and makes it particularly ideal for corrosive environments such as in sulphuric acid applications. Characterised by these features, the Sulzer KnitMesh XCOAT is the world’s first, unique wire mesh mist eliminator being a fluoroplastic ‘monofilament’ and integrating all the valued advantages of metal wire mesh pads.

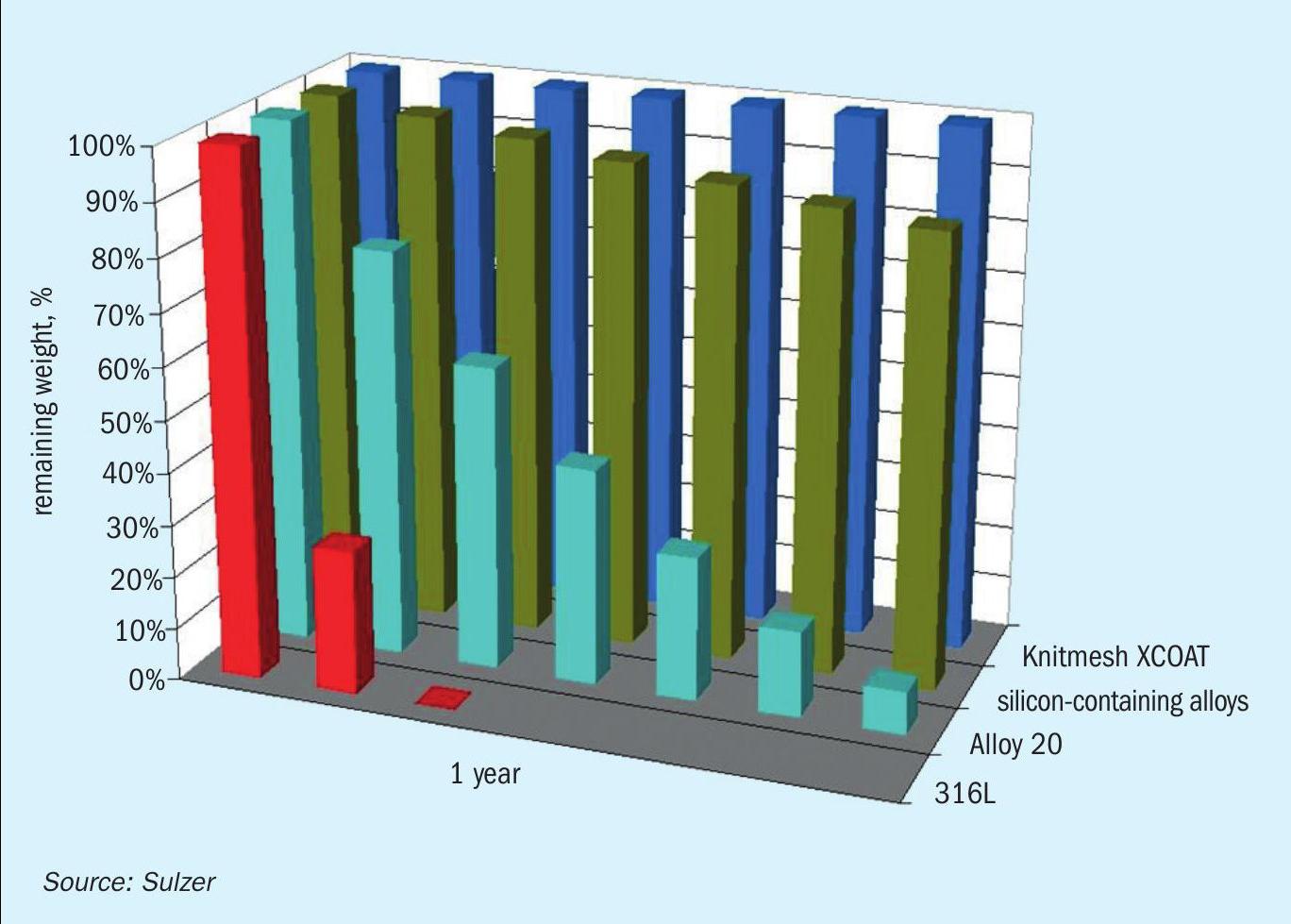

Field and lab tests have been conducted to demonstrate the corrosion resistance of the Sulzer KnitMesh XCOAT. Fig. 4 compares the corrosion of Sulzer XCOAT and various stainless steel and alloy wires in the presence of 93-98% sulphuric acid, at 60-80°C, over the period of one year.

Table 1 summarises the pros and cons of wire mesh mist eliminators made of different materials.

Case story

One of the world-leading sulphuric acid plant and clean technology providers contacted Sulzer for the replacement of a fluoroplastic build wire mesh mist eliminator in a SO2 -sulphuric acid wet gas scrubber in a zinc factory. The existing wire mesh pad was completely constructed of fluoroplastic with no metal or alloy as virtually no metal contamination (max. 25 ppb) is tolerated in the product stream. While the scrubber is operated at a relatively high operating temperature of around 120°C the existing fluoroplastic mesh pad showed very severe shrinkage (see Fig. 5), requiring replacement of the pad every six to ten months.

Once the mesh pad was replaced with the Sulzer KnitMesh XCOAT, shrinkage of the mist eliminator was no longer a problem. To meet the low metal contamination requirement in the product stream the metal grids of the KnitMesh XCOAT pad were also coated with a best-class fluoroplastic overlay for this service. Based on client’s information the KnitMesh XCOAT has been in service for many years without any requirement for replacement, and the payback for this turnaround was achieved in less than a year. Truly a big success story.

Conclusion

Benefits of longer turnaround cycles, payback and opex calculations as well as the maintenance culture have an impact on the selection process by plant management. The information provided in this article serves to explain the benefits of the Sulzer KnitMesh XCOAT mist eliminator as regards service life, efficiency, and capacity.