Sulphur 407 Jul-Aug 2023

31 July 2023

A beacon of energy-efficient waste heat recovery

HEAT RECOVERY

A beacon of energy-efficient waste heat recovery

The recovery of waste heat from Aurubis’ copper smelting operation in Hamburg is already helping to reduce global carbon emissions and has the potential to provide heat for up to 20,000 homes through the district heating network in Hamburg’s HafenCity. The energy for the network comes from waste heat that Aurubis recovers from their sulphuric acid plant, using unique Alfa Laval plate heat exchanger technology.

Recovering industrial waste heat is one of the most effective ways to improve energy efficiency on a global scale. By recovering energy that would otherwise be lost to the atmosphere or water and reusing it for other purposes, we can greatly reduce fuel consumption compared with today’s levels. As a result, we can also drastically reduce global carbon emissions. Aurubis has taken this approach to improve sustainability in one of their smelters. Partnering with the German energy supplier enercity Aktiengesellschaft, the multimetal company has become the driving force behind a district heating network that serves Hamburg’s HafenCity neighbourhood. The energy for the network comes from waste heat that Aurubis recovers from their nearby sulphuric acid plant, using unique Alfa Laval plate heat exchanger technology that is designed to resist corrosion and withstand the high pressure and extreme heat associated with the process.

Aurubis, one of the world’s largest producers and recyclers of copper, operates a large smelter on the island of Peute, located in the Elbe River, in the heart of Hamburg. Sulphur dioxide gas is a by-product of the pyrometallurgical copper process used here. In the sulphuric acid plant, this gas is converted first to sulphur trioxide and subsequently to liquid sulphuric acid. The sulphuric acid is continuously diluted in the process. Acid dilution is a highly exothermic process, which releases significant amounts of heat. Thanks to Alfa Laval GPHE (gasketed plate heat exchanger), this heat can be recovered by Aurubis for use in district heating.

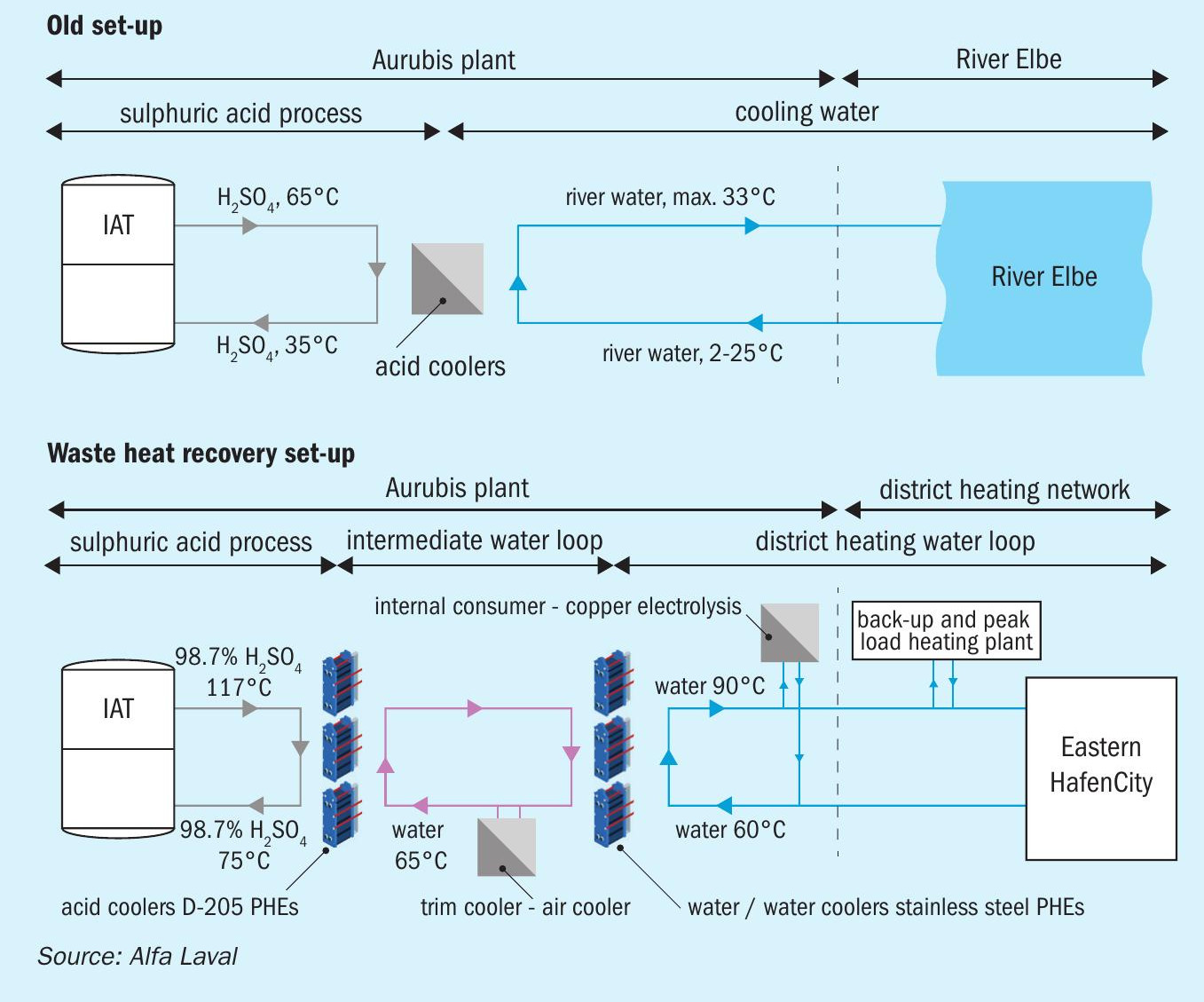

The sulphuric acid production takes place in the smelter’s contact plant. At the heart of the plant lies an intermediate absorption tower. The heat of dilution from this step was originally cooled with river water from the Elbe and thus left unutilised. The aim of Aurubis’ collaborative project with enercity was to use heat exchangers to recover energy from this process, and to put that energy back to use sustainably by funnelling it into the Hafen-City district heating network.

Equipment design and materials

Aurubis’ preliminary challenge was that hot water used in this type of district heating scheme needs to have an initial temperature of at least 90°C. As a result, they had to begin by building a completely redesigned intermediate absorption tower (IAT), increasing the process temperature of the concentrated sulphuric acid to approximately 120°C, a temperature increase of nearly 50°C.

However, this new intermediate absorption tower added further complications to the already demanding project of designing a heat recovery system involving a substance as challenging as sulphuric acid. The higher process temperature substantially increased the corrosiveness of the medium.

This posed a particularly difficult challenge for the heat exchangers in the project, which needed to be constructed of highly corrosion-resistant materials in addition to being able to handle high pressures and temperatures, and to offer extremely high thermal performance to ensure an efficient transfer of heat from the Aurubis process to the district heating network.

Aurubis contacted Alfa Laval, who worked with the copper producer to design customised plate heat exchangers, fully adapted to the demanding process environment. The final system was comprised of eight heat exchangers featuring stateof-the-art channel plate designs. Three of the heat exchangers – the intermediate absorption tower coolers – were semi-welded units, made in Hastelloy D-205™ material, a nickel-based alloy that is particularly resistant to sulphuric acid corrosion. D-205™ has delivered a proven performance at many sulphuric acid plants across the globe since the 1990s. With more than 300 D-205 units installed worldwide, this tried-and-tested material was the obvious choice for ensuring reliable, safe, and efficient operation. The remaining five heat exchangers in the system are fully gasketed plate heat exchangers: three water-water heat exchangers, and two acid-acid interchangers.

Unlike traditional gasketed plate-andframe heat exchangers, the Alfa Laval semi-welded design is capable of resisting mechanical fatigue in applications with high design pressures and temperatures. The unique plate design also ensures very high thermal efficiency, with a temperature approach as low as 3°C. This means that the water medium used to transfer heat to the district heating network can leave the heat exchanger only a few degrees cooler than the hot acid entering the unit. Additionally, plate heat exchangers are more compact, allowing for easier, more cost-effective installation in a fraction of the space.

Fig. 1 shows the old set-up and the new waste heat recovery set-up.

Improving sustainability

Waste heat that was previously lost 0 to the river Elbe is currently heating up to 1,000 900 800 8,000 homes through the district heating network in Hamburg’s HafenCity, resulting in a reduction in CO2 emissions of up to 20,000 t/a.

On completion of the project next year when the remaining two lines will be equipped with waste heat recovery equipment the plant will have the potential to heat up to 20,000 homes, with up to 100,000 t/a reduction in CO2 emissions.

An additional benefit is that Aurubis no longer needs to rely on cooling water taken from the Elbe River, which further benefits the local ecology. The German Energy Agency has recognised the project as a “beacon of energy-efficient waste-heat utilisation.”

Almost every city has untapped heat sources like Aurubis and Alfa Laval’s heat transfer solutions make it possible to harness that energy and reduce carbon emissions.

Energy efficiency is one of the main contributors to reaching net zero, and increased efficiency could account for 50% of emissions reductions towards 2030.

The challenge though is to figure out what works best for every specific use case. To help with this Alfa Laval has developed a calculator where it’s easy to input a system’s current configuration and then get suggestions for potential tweaks and upgrades. Case by case the energy saving can be impressive, but the real impact comes from doing this at scale.