Fertilizer International 520 May-Jun 2024

31 May 2024

Enhanced efficiency fertilizers for advanced nitrogen management

THE EEF MARKET

Enhanced efficiency fertilizers for advanced nitrogen management

Addressing the ‘leaky’ nature of nitrogen fertilizers is a longstanding priority for growers, fertilizer producers and retailers alike. Dr Karl Wyant, Nutrien’s Director of Agronomy, examines the valuable role enhanced efficiency fertilizers (EEFs) can play in improving nitrogen use efficiency.

Introduction

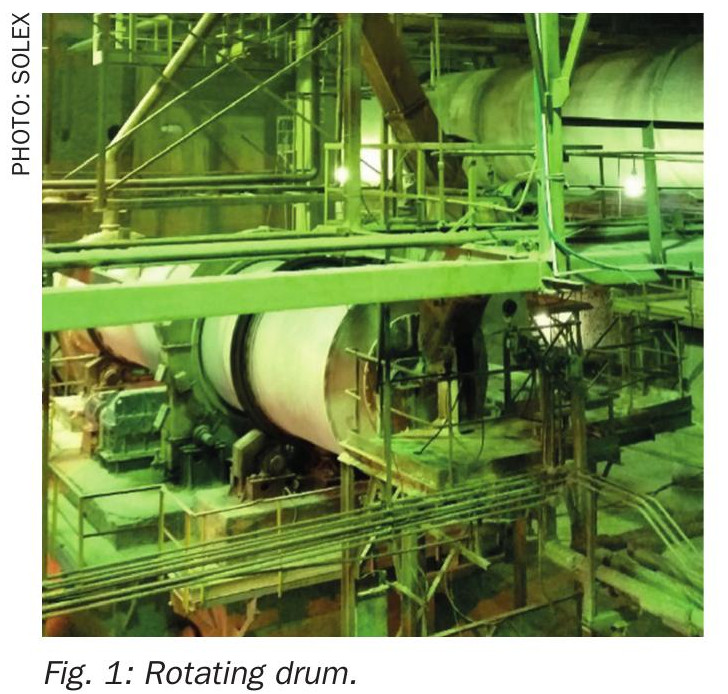

Growers continue to face the task of improving nutrient use efficiency. For nitrogen fertilizers (urea, ammonium sulphate, liquid urea ammonium nitrate, etc.), this is a dual challenge requiring higher crop uptake of nitrogen, relative to the amount applied, and reducing environmental impacts by closing off the multiple pathways for nitrogen loss in the field1 (Figure 1).

Traditional nitrogen applications, even with careful management, can still result in significant field losses which reduce the overall nitrogen use efficiency of the crop (Table 1). The main loss pathways for specific forms of nitrogen in the fertilizer and the soil (NO3 – nitrate, NH4 + ammonium, NH3 ammonia and N2 nitrogen gas) are as follows:

- Leaching of nitrates occurs when water passing through the soil beyond the root zone transports nitrate with it. Nitrate easily leaches through sandy and other permeable soils. Leaching also occurs when nitrate fertilizers or pre-existing nitrates in the soil are exposed to strong rainfall events or irrigation. Nitrogen leaching losses can reach up to 50 percent of total applied N.

- Volatilisation is the loss of nitrogen as ammonia gas (NH3 ). It commonly occurs when urea or urea ammonium nitrate (UAN) liquid fertilizers (e.g., UAN 32) are on or near the soil surface. Nitrogen volatilisation losses can be as high as 40 percent of total applied N.

- Denitrification occurs when oxygen is deficient in the soil and anaerobic bacteria convert nitrate to various nitrogen gases (N2 etc.) which then escape resulting in nitrogen loss. Denitrification often occurs after rain events when soils are waterlogged. Denitrification can result in nitrogen losses of up to 50 percent of total applied N.

- Soil erosion can cause nitrogen losses (NH4 +) of up to 20 percent of total applied N.

Losing nitrogen fertilizers to leaching, volatilisation, erosion, or denitrification means they are unable to drive crop growth and yield and has the potential to pollute the environment.

Improving nitrogen use efficiency – fertilizer formulations

To drive up nitrogen use efficiency (e.g., delivering more harvested crop per unit of applied nitrogen), the fertilizer industry has created various formulations designed to help increase nitrogen uptake by the crop – by retaining the applied nitrogen in the soil and reducing the risk of potential nitrogen losses1 . Broadly, this category of fertilizers is known as enhanced efficiency fertilizers (EEFs) with several options to choose from (Figure 2).

EEFs are defined by the Association of American Plant Food Control Officials (AAP-FCO) as:

“Any fertilizer product that reduces nutrient losses to the environment while increasing nutrient availability for the crop.”

These products generally function by either controlling/slowing the release of nutrients or by helping prevent the soil reactions that lead to nutrient losses.

Categories of EEFs include slow-release fertilizers (SRFs), controlled-release fertilizers (CRFs), and stabilised fertilizers (SFs):

- Stabilised fertilizers (SFs). These incorporate a stabiliser or chemical inhibitor to slow biological (microbial) transformations of nitrogen in the soil (e.g., urea to ammonia, ammonia to nitrate, etc.). The duration of the inhibition or stabilisation effect is determined by the active ingredient used and its concentration. Inhibiting or slowing the biological processes reduces the risk of nitrogen loss by preventing excess accumulation of either ammonia or nitrate.

- Slow-release fertilizers (SRFs). These products release nitrogen by biochemical breakdown. Release time is determined by the nature and/or chain length of the nitrogen compound present and the biological activity of the soil.

- Controlled-release fertilizers (CRFs). These coated granular products release nitrogen by diffusion through the coating when in contact with soil moisture and temperature. Release rate is controlled by coating thickness, coating type and soil temperature.

Choosing the right EEF

The obvious dilemma for growers, when trying to improve the overall nitrogen use efficiency of their crop growing programme, is which EEF to select – especially given the many options and brand names on the market. In making the right decision, it ucts is can then be categorised on this basis, helpful to ask two essential questions: as shown in Figure 3. 1. How long do I need to protect my Stabilised fertilisers that incorporate nitrogen? inhibitors (e.g., urease and nitrification 2. Which loss pathway(s) do I need inhibitors) tend to protect against a specific protect against? pathway and offer a comparatively short duration of protection. Slow- and controlled-release fertilizers that function via biochemi-Answering these questions will help growers to select the product with, firstly, the cal or physical protection, meanwhile, tend right mode of action and, secondly, the to guard against a wider spectrum of losses most suitable duration of protection. Prod- over a longer period (Figure 3).

Beyond EEFs and the role of the 4Rs

A quick review of the basics of nitrogen fertilizer application can help improve uptake efficiency when used in conjunction with an EEF. The four main management factors that help improve the efficiency of applied nitrogen fertilizers are commonly known as the 4R’s:

- Right application rate – how much nitrogen do you need?

- Right formulation – nitrogen fertilizer type and EEF selection

- Right timing of application – match nitrogen application to crop uptake rates

- Right placement – place the nitrogen where the crop can access it.

Along with the 4R guidelines, holistic crop and nutrient management should focus on the following to help promote the proper use of fertilizers1 :

- Promoting root growth by improving soil structure (good soil aeration, storage, and supply of water), soil pH management (liming), the creation of soil organic matter, and promoting soil health. Strong, vigorous crops will make good use of applied fertilizers.

- Using soil and plant analyses for nutrient planning and to constantly monitor crop growth and development.

- Applying amounts of nutrients that correspond as precisely as possible to crop needs, growing conditions, and realistic yield performance.

Concluding comments

Fertilizers plays a critical role in meeting the increased global demand for food, fibre, and fuel. They must, however, be applied safely, effectively, and efficiently to prevent wasted input dollars and reduce risks to the environment. Using an enhanced efficiency fertilizer (EEF), alongside proper 4R nutrient stewardship guidelines, has the potential to greatly increase nutrient use efficiency across the globe.

As covered here, growers face many challenges when making effective crop fertilization management decisions. Selecting the right nitrogen source, rate, time, and application method (4Rs) is critical – as is choosing the right EEF based on local conditions. Matching the EEF with the specific nitrogen loss pathway and the duration of protection required will help ensure a good return on investment and less errant fertilizer behaviour in the environment.

SPOTLIGHT ON ESN ®

Controlled-release fertilizers (CRFs) are a popular type of EEF defined by the AAP-FCO as follows:

“A CRF has been engineered to provide nutrients over time at a very predictable rate under specific conditions (e.g., 3 month release at 21°C).”

CRFs are typically coated with polymer membranes to help control the release of nutrients to the soil (Fig. 4). Nutrien’s ESN ® (44-0-0) is a successful CRF product that has been on the market for many years – and provides a good example of how polymer-coated urea (PCU) formulations work.

ESN ® technology encapsulate urea granules within a flexible polymer coating which protects against the nitrogen loss pathways discussed previously. This protection is especially valuable when high nitrogen rates are applied at times when crop demand is low.

The unique polymer coating releases nitrogen based on the two requirements for crop growth: soil moisture and temperature (Fig. 4). Moisture creates a nitrogen solution inside the coating. This then moves through the coating at a rate based on soil temperature. The release of nitrogen increases as soil temperatures rises and, conversely, the rate of nitrogen release slows when the soil cools or is cold. The positive correlation between soil temperature and nitrogen release from ESN ® also matches rising crop demand for nitrogen as, similarly, plant growth also increases as soils become warmer.

References and bibliography