Fertilizer International 520 May-Jun 2024

31 May 2024

RNZ – Innovations for sustainable agriculture

COMPANY PROFILE

RNZ – Innovations for sustainable agriculture

RNZ Group is positioning itself as the most innovative and sustainable fertilizer producer in the UAE. In partnership with Shell, the company has been manufacturing sulphur-enhanced fertilizers using Thiogro technology since the end of 2022. Raza Soomar, RNZ’s managing director, provides an overview of the company and highlights recent business successes.

Introduction

Dubai-headquartered RNZ Group is a leading supplier of water-soluble fertilizers, granular NPK grades and organic fertilizers to the Middle East, Africa and Southern Asia (MEASA) region. The company’s fully automatic NPK blending and granulation plant, set up in the United Arab Emirates (UAE) in 2011, has a combined production capacity of 105,000 t/a.

Notable RNZ product lines include:

- Granular NPK fertilizers: 60,000 t/a production capacity, 200 formulations

- Water-soluble fertilizers: 40,000 t/a production capacity, 400 formulation

- Suspension fertilizers: special formulations for precision agriculture

- Straight fertilizers: international supply partnerships with leading producers.

These operational capabilities for customised and crop-specific fertilizer grades are supported in-house by state-of-the-art R&D facilities.

RNZ is also the region’s first producer of sulphur-enhanced urea products which are marketed under the Purti NS Plus brand name. These are manufactured using patented Thiogro technology in partnership with Shell. The production plant for these products was successfully commissioned in Kizad, UAE, in December 2022.

The Purti NS Plus range is manufactured with 100 percent local input materials and includes NS10+ (10-0-0+75S) and NS20+ (20-0-0+50S) formulations. NS20+ is produced for the local market and tailored for specific soil issues and crop nutrition needs in the UAE.

The beneficial effects of these sulphur-enhanced fertilizers include:

- Reducing pH. The sulphur oxidation process helps reduce pH in the active root zone.

- Releasing nutrients. More nutrients (calcium, iron manganese and zinc) are available for uptake in treated soils.

- Sulphate availability. Pre-harvest sulphate levels are higher in treated soils.

- High bioactivity. Beneficial microbes are more active in treated soils thanks to the sulphur oxidation process.

RNZ has also successfully developed the HydroMaster specialty fertilizer range. These are specifically formulated for hydroponics and vertical farms. The company is the exclusive supplier to Bustanica, the world’ largest vertical farm located at Dubai in the UAE.

The food security challenge

Subsidiary company RNZ Agrotech Limited was established in 2020 to contribute to the objectives of the UAE’s National Food Security Strategy. This is aiming to achieve zero hunger by 2050 by ensuring the whole population has access to safe and nutritious food. Achieving this goal will require the widespread adoption of sustainable agricultural practices that increase crop productivity while protecting ecosystems.

The UAE has major food security challenges being an arid country with water scarcity and limited arable land that faces extreme weather conditions throughout the year. RNZ is helping address these challenges by championing innovation and collaboration in the MEASA region. The company is working with multidisciplinary teams from internationally-renowned organisations to develop innovative low-carbon and sustainable fertilizer manufacturing technologies.

Centre of Excellence

RNZ Group set up the Centre of Excellence for Fertilizer Technology Research (COE-FTR) in Kizad, Abu Dhabi, in 2020. This state-of-the-art centre is the first of its kind for fertilizer science and technology research in the UAE.

The COE-FTR is dedicated to research, development and the commercialisation of innovative and climate-smart fertilizers. The centre’s advanced laboratories are well equipped with instruments for the characterisation and analysis of fertilizer materials and offers:

- Chemical analysis of more than 30 major elements and microelements

- Full soil testing including pH, EC, C/N, organic matter, microbial counts and soil chemistry

- Full water testing including water hardness, pH, EC, nitrates and other chemical elements

- Full plant tissue analysis for major and micronutrients, nutrient ratios, biomass and crop health indicators.

COE-FTR also includes an incubation centre and pilot-scale product testing and production facilities. The centre works in collaborations with prestigious partners such as UAE University, Shell and Bustanica.

Research and development at the COE- FTR focuses on six priority areas.

- Value-added and climate-smart fertilizers. This includes the commercialisation of advanced inorganic, organic, hybrid, nano and smart fertilizers that incorporate stabilisers, inhibitors, and coatings. These innovative products are designed for controlled nutrient release, better nutrient use efficiency and lower environmental footprints.

- Customised fertilizer technologies and guidance to growers. The centre develops and validates customised fertilizer products, based on soil health data, and provides guidance on balanced fertilization. Field tests are conducted to confirm on-farm performance prior to commercialisation. A complete fertilizer range for hydroponics has been developed and commercialised using RNZ’s in-house R&D capabilities.

- Recycling biowastes and managing soil health. Using a circular economy approach, soil carbon stocks can be improved using tailor-made organic fertilizers based on locally available biowastes. Increasing the organic carbon content of soil also enhances the nutrient use efficiency of inorganic fertilizers. Efforts are also being made to recycle urban municipal waste and convert it into compost with a carbon content of more than 10 percent.

“RNZ is the region’s first producer of sulphur-enhanced urea products which are marketed under the Purti NS Plus brand name.”

- Pilot plant tests. An in-house pilot plant facility enables RNZ to validate new fertilizer manufacturing technologies prior to scale-up, commercial production and marketing. RNZ has a dedicated technology scale-up team that works with internal and external experts to assess the technical and commercial feasibility of manufacturing value-added and new fertilizers.

- Setting up an Agri-Tech incubator.

This provides the resources and an environment where fresh ideas and innovation can succeed, with a special focus on encouraging and supporting young people and women. The incubator enables RNZ’s team to test and validate new product formulations and services.

- Strengthening dialogues, policies and regulations. The centre encourages growth and investment in the fertilizer sector by providing a forum for dialogue and brainstorming with external stakeholders. Technical guidance and support can also help assess current fertilizer practices and their impacts, and provide evidence for policy, regulation and environmental protection. Proactive engagement with government over mandatory compliance issues is also valuable. Overall, the task of policy advocacy becomes much simpler and more effective by engaging with all stakeholders in society.

Sustainability commitments

RNZ Group is implementing a new manufacturing model for value-added and hybrid inorganic-organic fertilizers based on circular economy principles, renewable energy and the recycling of materials. The company’s processes are being optimised to support the UAE’s sustainability ambitions and meet the goals of the United Nations Global Compact (UNGC) and UAE Alliance for Climate Action (UACA).

RNZ is planning to move beyond net zero and become carbon positive by:

- Moving to a circular production model with zero waste

- Adopting renewable power sources for its energy needs – including solar power installations at its Jebel Ali and Kizad sites

Running vehicles on biofuels and using electric forklifts.

Conclusion

Fertilizers are crucial inputs that will undoubtedly play an important role in the future of food security. Their production and costs are largely dependent on the availability of feedstock materials. Recent geopolitical risks have led to serious increases in fertilizer costs and subsequently higher food prices. This has led RNZ to create an international centre for advanced research on fertilizer technologies. This centre can help to tackle the geopolitical pressures placed on farmers and consumers by developing sustainable, efficient and innovative agricultural inputs.

PURTI NS PLUS – RNZ’S FLAGSHIP FERTILIZER RANGE

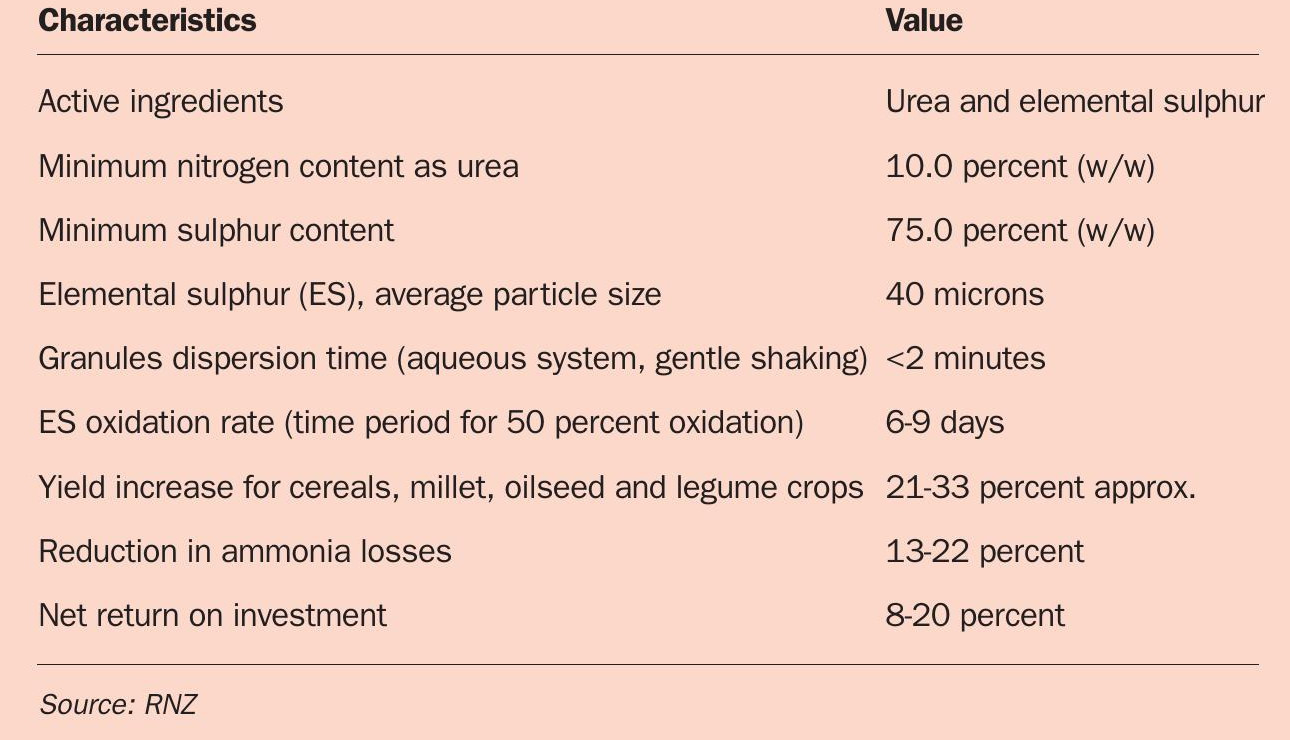

RNZ, in collaboration with Shell, has introduced patented Thiogro technology to the region via the innovative Purti NS Plus range, including the highly concentrated NS10+ (10-0-0+75S) sulphur fertilizer. The composition of this sulphur-enhanced urea product is as follows:

- Total urea content: 10.0 percent minimum by weight

- Total elemental sulphur (ES) content: 75.0 percent minimum by weight

- Moisture content: 0.5 percent maximum by weight.

Detailed product characteristics are set out in Table 1.

Features and benefits

RNZ’s NS10+ product is a sulphur-enhanced nitrogen fertilizer that combines micronised elemental sulphur with urea using patented Thiogro technology. It is designed to increase crop yields, improve farm productivity and reduce input costs. Benefits include:

- Providing critical nitrogen (N) and sulphur (S) crop nutrients in one application

- Enhanced nitrogen and sulphur use efficiency

- Prevents nutrient overapplication and reduces nutrient losses

- Increased soil microbial biomass and activity

- Higher crop yields and better quality produce.

RNZ NS10+ is designed to meet the early nitrogen and sulphur requirements of crops before and after their planting or emergence. This allows the crop’s remaining nitrogen requirements to be applied as a top-dressing during vegetative growth stages at ‘the right time’ – as recommended by the 4Rs. This avoids excessive nitrogen fertilization, leaching, or volatilization, and enhances the use efficiency of both nutrients. Higher nitrogen use efficiency – by lowering the loss of applied nitrogen – reduces both input costs and environmental impacts.

Sulphur is known to act in synergy with nitrogen, with poor sulphur availability affecting nitrogen use efficiency. Conversely, when applied together, nitrogen and sulphur can improve their combined agronomic efficiency compared to individual applications.

RNZ NS product variants

RNZ SB product variants

Crop trial results

A series of field trials were carried out using treatments with Purti NS Plus fertilizers. In all crops, these treatments significantly increased yields and improved crop quality as follows:

- Wheat. Significant increases in effective tillers, spike length, number of grains per spike, and 1,000 seed weight. These improvements generated an increase in net return of up to 22 percent.

- Maize. Significant increases in plant height, cob length, cob girth, number of rows per cobs, number of grains per cob and 1,000 grain weight.

- Mustard. Significant increases in primary and secondary branches per plant, silique length, total number of siliques per plant, grain numbers per silique, 1,000 seed weight, and seed, stover and biological yield. There was also an increase in electrical conductivity and available soil N and S.

- Potato. Significant increases in number of stems per plant, number of tubers per plant, weight of tubers per stem and tuber yield.

Value-added elemental sulphur fertilizers

RNZ’s Centre of Excellence is also developing new value-added sulphur fertilizer formulations to meet the nutrient needs of growers worldwide. These include NS+ and sulphur-bentonite products enriched with micronutrients such as zinc, boron and selenium.