Sulphur 414 Sep-Oct 2024

30 September 2024

Real-time SO2 leak detection

EMISSIONS MONITORING

Real-time SO2 leak detection

Optical gas imaging technology, enhanced by artificial intelligence, offers a groundbreaking approach to monitoring SO2 emissions in real time. Andrés Russu of SENSIA introduces SENSIA’s RedLook solution which offers fully autonomous, 24/7 continuous monitoring of SO2 leaks, providing industries with the tools they need to maintain environmental integrity and operational safety.

In an era where industrial operations in modern economies are at risk due to their environmental impact on surrounding communities, it is critical to implement technological solutions that promote sustainability in heavy industries so that they can continue contributing to economic prosperity. One of the most significant environmental impacts comes from the effect of pollutant gas emissions on air quality. Among these gases, sulphur dioxide (SO2 ) stands out due to its significant contribution to local air contamination and acid rain. Real-time detection of SO2 leaks is paramount for ensuring air quality and compliance with stringent environmental regulations. Optical gas imaging (OGI) technology, enhanced by artificial intelligence (AI), offers a groundbreaking approach to monitoring SO2 emissions, providing industries with the tools they need to maintain environmental integrity and operational safety.

Optical gas imaging: How infrared works

OGI is a powerful and established technology that enables the visualisation of gas emissions that are invisible to the naked eye. OGI leverages infrared (IR) imaging where a spectrally tuned camera sees the thermal radiation emitted or absorbed by objects and gases and transforms this radiation into visible images. In the case of SO2 , which absorbs IR radiation at a sub-band within the long wave infrared (LWIR) spectrum, OGI cameras can detect and visualise the presence of gas emissions, providing real-time insights into leak sources. OGI cameras allow operators to see gas leaking from compressors, pipelines, pumps, flanges and other industrial equipment. This visual representation of gas emissions is crucial for rapidly identifying leaks, already a standard in the oil and gas industry for the detection of methane and hydrocarbons in leak detection and repair (LDAR) campaigns. SENSIA OGI technology can also quantify the gas leak size, enabling industries to make informed decisions in terms of maintenance, and subsequently address it.

Sulphur dioxide and detection with IR

Sulphur dioxide is commonly produced in essential industrial processes such as metal smelting and the production of sulphuric acid. It is a significant pollutant, contributing to respiratory and cardiovascular illness in humans and forming acid rain, which can have devastating effects on ecosystems and infrastructure. The detection of SO2 is critical not only for environmental protection but also for the safety of industrial facilities and surrounding communities.

The ability of SO2 to interact with IR radiation makes it detectable by OGI cameras. These cameras are designed to be sensitive to the specific wavelengths at which SO2 absorbs and emits radiation, allowing for the precise identification and visualisation of SO2 leaks. This capability is particularly valuable in industrial sites where SO2 emissions need to be closely monitored to prevent environmental contamination and ensure compliance with regulatory standards.

The danger of poor SO2 emissions management

Poor management of SO2 emissions can have severe health, environmental and financial consequences. When released into the atmosphere, SO2 can react with other compounds to form fine particulate matter (PM2.5), a major component of air pollution that can penetrate deep into the lungs and cause respiratory illnesses, cardiovascular diseases, and other health issues. Additionally, SO2 can combine with water vapour to form sulphuric acid, leading to acid rain. Acid rain has a corrosive effect on buildings, infrastructure, and natural ecosystems, damaging forests, lakes, soil and heavily damaging equipment near leak sources.

Organisations that fail to adequately control their SO2 emissions risk not only legal penalties but also the potential for significant environmental damage, harm to public health, and faster deterioration of operational assets. Because of this, most industrialised countries have enacted regulations regarding SO2 emissions such as the National Ambient Air Quality Standards (NAAQS) established by the Environmental Protection Agency (EPA) in the United States, Directive 2008/50/ EC (also known as the Ambient Air Quality Directive) in the European Union and the Gothenburg Protocol internationally, which establish standards and commitments for reducing SO2 emissions.

Compliance with these regulations is a common challenge for industries operating in sectors where SO2 emissions are prevalent. Failure to adhere to these standards can result in hefty fines, legal action, and irreparable reputational damage. As such, the ability to accurately monitor and manage SO2 emissions is a critical component of any industrial operation. SENSIA’s RedLook infrared imaging technology provides a tried and tested solution for SO2 fugitive emission detection.

SENSIA’s RedLook technology

SENSIA, a leader in AI-powered infrared imaging technology with systems operating worldwide, has developed RedLook, a comprehensive OGI-based solution designed for 24/7 automatic operation and real-time gas detection among multiple other applications.

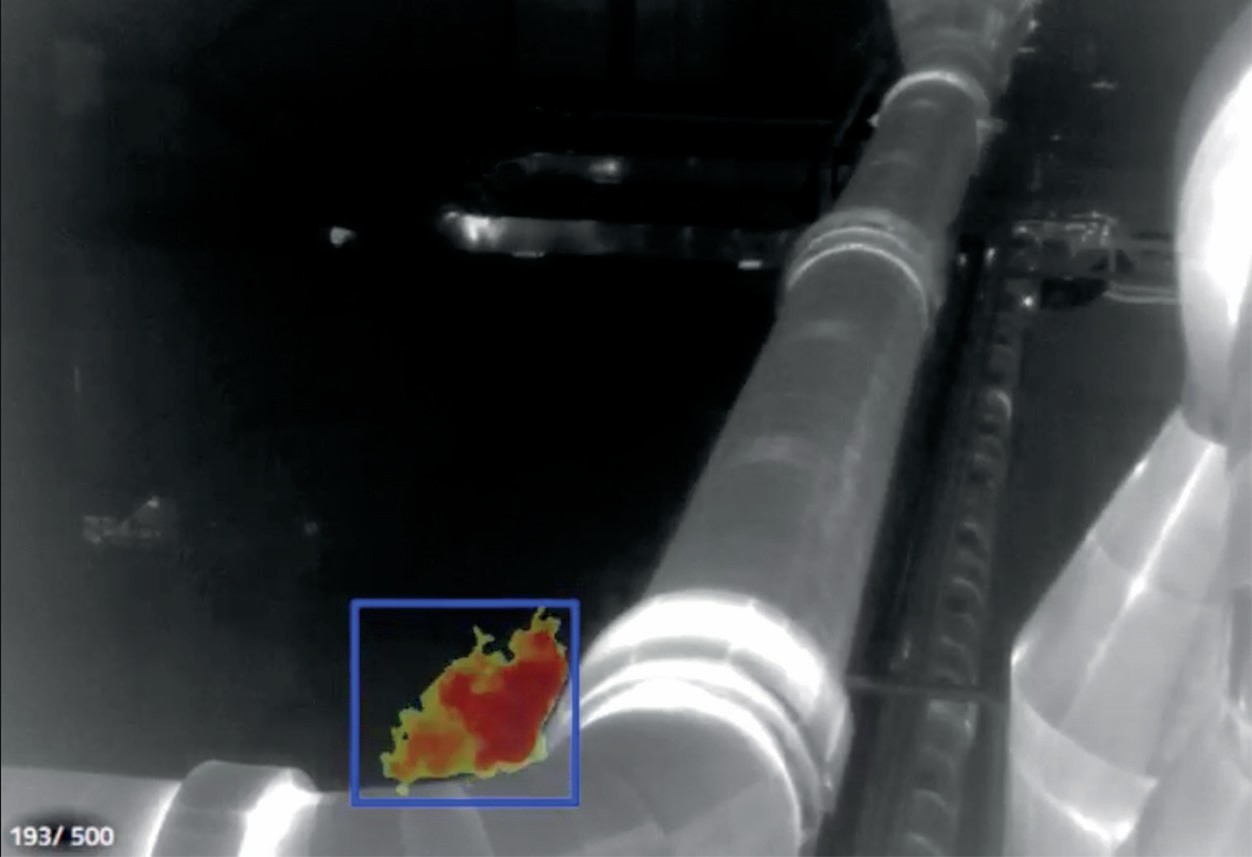

During the past few decades, OGI technology has always required human supervision (camera operators) to benefit from its gas detection capabilities. In the current global scene, SENSIA is the pioneer in evolving OGI technology from the past into more complex and advanced systems that allow fully autonomous operation. RedLook’s continuous monitoring technology combines computer vision and artificial intelligence to provide automated real-time classification and information on everything of interest to its customers, such as gas detection alarms and gas leak flow rates, the combustion efficiency of flares, early flame detection alarms, monitoring temperature levels of critical components, or controlling intrusions into forbidden areas.

The reliability of the detection provided by RedLook’s artificial intelligence algorithms has, in many cases, even surpassed the human observer. Additionally, thanks to its great versatility and interconnectivity with third-party systems, RedLook has become an indispensable technology for industrial plant operators, as it enables preventive maintenance, safety, and environmental compliance strategies without human cost or risk while increasing operational efficiency. RedLook for SO2 detection utilises cutting-edge OGI cameras, the Caroline FY continuous monitoring OGI for autonomous site scanning in industrial facilities and the portable Caroline Y OGI for field inspections and surveys. These cameras are specifically engineered to detect SO2 and other industrial gases, providing operators with the tools they need to manage fugitive emissions effectively.

A pioneer in infrared imaging

Based in Madrid, Spain, SENSIA has over 15 years of experience in developing innovative infrared imaging technology for gas detection and other industrial cases of use. SENSIA is the IR provider with the highest level of control over its proprietary technology, fully developing the hardware, software and analytics of our solutions, allowing it to offer a very distinctive added value compared to its competitors. SENSIA is always at the forefront in terms of infrared remote monitoring technology and innovation and has recurrently been the pioneer IR manufacturer in the world, providing benefits to the industry such as, but not limited to, the first automated continuous monitoring OGI-based system, the first uncooled handheld OGI camera, the first built-in quantification analytics on handheld OGI, and the first bi-spectral OGI for flare efficiency monitoring. This continuous innovation enables its customers to benefit from a level of performance and reliability that is far superior to other alternatives.

SENSIA specialises in AI-driven solutions for gas detection, but its capabilities also include fire detection, flare efficiency monitoring, intelligent thermography for preventive maintenance, surveillance, and more. With a strong presence in more than 40 countries and a global distributor network, SENSIA has established itself as a trusted provider of advanced imaging technology for industries such as oil and gas, security, defence, and chemical manufacturing.

SENSIA’s proprietary solution, RedLook, is designed to meet the diverse needs of its clients, ensuring accuracy, reliability, compliance with regulatory standards and increased safety. The complete RedLook solution is the result of SENSIA’s expertise in infrared imaging and AI, offering state-of-the-art, multifunctional systems empowering companies to overcome their HSE challenges.

RedLook solution for SO2

RedLook is a fully integrated system that combines high-performance continuous monitoring cameras, advanced analytics, and user-friendly software to deliver unparalleled performance in gas detection. The system is designed to be scalable and adaptable, making it suitable for a wide range of industrial applications.

The Caroline Y camera, part of the RedLook solution, is a portable OGI device that allows operators to conduct field inspections and surveys with ease. Its lightweight design and powerful imaging capabilities make it ideal for detecting SO2 fugitive emissions in remote or hard-to-reach areas. Meanwhile, the Caroline FY camera is designed for autonomous continuous monitoring in industrial facilities, providing real-time video and data on SO2 emissions and alerting operators to any irregularities.

RedLook’s analytics software is powered by physics-guided AI, enabling the system to automatically detect SO2 leaks with a high degree of sensitivity. The software also generates videos and detailed and automated reports, helping operators to document compliance with regulatory standards and track the effectiveness of their emissions management strategies.

Advantages of RedLook

When compared to traditional gas detection methods such as point detectors, SENSIA’s RedLook technology offers several distinct advantages:

l Greater sense of awareness: The high-quality real time IR video can provide a clear understanding of the nature and magnitude of the gas emissions occurring.

l Visual identification and pinpointing of the emission sources that allow more accurate and faster response from the site operators: It is essential for repair efforts to spot the leak source immediately and gain visible evidence of emissions and repair results.

l Faster, real-time monitoring for efficient leak detection: Rather than waiting for concentrations to reach minimum thresholds of point detectors, SENSIA’s RedLook can detect leaks immediately as they occur.

l AI-powered analytics for low false alarm rates and immediate alerts: RedLook’s powerful artificial intelligence algorithms are based on laws of physics, thousands of data points and scenario-based tuning techniques to provide the must trustworthy solution on the market.

l Remote, long-range detection: Eliminating the need for direct contact with the gas, SENSIA’s OGI technology can detect leaks remotely. In addition to this, Red-Look eliminates the difficulty/inability of single point detectors to monitor emission sources on elevated locations.

l Multifunctionality: RedLook not just replaces gas sensors, it also replaces flame and perimeter security sensors with the same camera system.

l Wider range of coverage: Customisable lenses and pan-and-tilt features allow our cameras to autonomously scan wide areas of a facility or dynamic locations.

l No dependence on wind direction: Unlike traditional point detectors, RedLook image-based detection can effectively spot SO2 leaks no matter the wind direction.

l No calibration or replacements required: our intrinsically safe and anti-corrosive systems last over ten years.

Case studies of RedLook technology: Aurubis and Rio Tinto

The adoption of SENSIA’s RedLook technology has already yielded impressive results in the field.

For instance, Aurubis, an influential global provider of copper and other metals, has integrated RedLook into its operations to detect SO2 emissions in real time. The first project became such an internal success for the company that they decided to extend the solution to a different sector of the plant just a few years after. The purpose of RedLook for Aurubis was to monitor the outflowing SO2 pipe from the smelting furnace, which crosses near the offices area implying a direct risk for Aurubis personnel in case of an SO2 leak. To solve this, SENSIA deployed a turn-key project based on RedLook with four continuous monitoring Caroline FY cameras plus three additional units for the second phase. Given the harsh environment in this area of the plant, the cameras, and the rest of the accessory equipment were specially designed using anti-corrosive enclosures with pressurised air systems.

Prior to RedLook, the detection and repair activities of leaking equipment were simultaneously performed during the scheduled maintenance shutdowns of the plant. On many occasions, it was not feasible to spot the source of the leak and determine which component was defective. In addition to this, once the failure was identified there wasn’t enough time left during the maintenance stop to order, receive, and replace these components so the repair couldn’t be carried out until the next scheduled shutdown resulting in permanent SO2 emissions for prolonged periods of time. Thanks to RedLook, the inspection times to spot SO2 leaks in the plant were drastically reduced in relation to the previously used methodology, not only leading to the consequent decrease in the net amount of SO2 emissions to the atmosphere but also having a critical impact in terms of cost saving for Aurubis. These situations, now part of the past, illustrate the benefits of adopting RedLook technology, which is now seamlessly integrated within the Aurubis distributed control system (DCS) and video management system (VMS).

Similarly, Rio Tinto, another global leader in mining and metals, has recently implemented RedLook for continuous monitoring of SO2 emissions at its refining facilities in the United States. Also deployed as a turn-key solution, RedLook has enabled Rio Tinto to optimise maintenance costs while spotting fugitive SO2 emissions in multiple critical sectors of their site, including the acid plant and the conversion process equipment. For Rio Tinto, it was crucial to detect all the emissions occurring in these areas where the gas temperature and the SO2 concentration are very high, causing a fast deterioration of the affected components if immediate action is not taken. For this reason, RedLook is now considered a critical system for Rio Tinto that allows them to significantly reduce operation costs and optimise maintenance activities.

Conclusion

The use of AI-powered IR imaging for sulphur dioxide leak detection represents a significant advancement in sustainability and efficiency of industrial operations. SENSIA’s RedLook solution offers fully autonomous, 24/7 continuous monitoring of SO2 leaks, enabling a cost-effective preventive maintenance strategy, seamlessly connected to the digital ecosystem of the operator (DCS, SCADA….) As regulations become increasingly intense and the need for sustainable practices grows, technologies like RedLook will play a crucial role in protecting both public health and the environment while saving maintenance costs for industrial operators.