Fertilizer International 524 Jan-Feb 2025

24 January 2025

Van Iperen’s Green Switch journey

SUSTAINABILITY

Van Iperen’s Green Switch journey

Van Iperen International is pursuing an ambitious sustainability strategy to cut its carbon footprint by 50% and switch production to innovative low-carbon crop nutrient products. In a partnership with Cinis Fertilizer, the company recently introduced GreenSwitch® Potassium, a sustainable potassium sulphate (SOP) fertilizer produced from industrial residues using a fossil fuel-free production process.

The crop nutrients and biostimulants company Van Iperen International is placing itself at the vanguard of the sustainability transition in agriculture, with a bold strategy to reduce the impacts of conventional mineral fertilizer production. The Netherlands-based company is planning to “change the rules of the game in plant nutrition” by making the circular economy and resource efficiency cornerstones of its operations – and providing growers with innovative products that make conventional agriculture more sustainable.

The future path set out by Van Iperen’s sustainability strategy is embodied by its evocative and inspirational name – the Green Switch Journey. It’s a strategy that is already delivering results.

Sustainable SOP with a low carbon footprint

Van Iperen has already made its first deliveries of GreenSwitch® Potassium to customers, the outcome of a successful ongoing partnership with Cinis Fertilizer (Fertilizer International 523, p38). This pure and fully water-soluble potassium sulphate (SOP) product – which is associated with significantly reduced CO2 production emissions – is suitable for foliar and fertigation applications.

GreenSwitch® Potassium is produced by Cinis Fertilizer at its newly opened 100,000 t/a capacity SOP plant at Örnsköldsvik, Köpmanholmen, Sweden. The Örnsköldsvik plant is powered by fossil-free and renewable energy and produces SOP from sodium sulphate (Na2 SO4 ) using patented technology. Cinis has contracts in place for upcycling sodium sulphate from industrial residues – including those from electric car battery manufacturing and ashes from pulp mills.

This first-of-its-kind production method – based on the glaserite process – uses half as much energy as conventional SOP production, according to Cinis. The company quotes an energy consumption of 50,000 MWh for its production process versus 100,000 MWh for conventional manufacture, based on 100,000 tonnes of SOP production.

The result is a fertilizer with a low carbon footprint that, say both companies, is making a “unique and circular contribution” to sustainable agriculture.

Green Switch projects and products

The introduction of sustainable SOP to the market is just the start of Van Iperen’s Green Switch Journey. The company has, in fact, a roster of groundbreaking new projects:

- GreenSwitch® Potassium, as already mentioned, is the outcome of a new business partnership with Sweden’s Cinis Fertilizer. A fossil fuel-free production process transforms industrial waste residues – from paper and electric car battery manufacturing – into sustainable potassium sulphate (SOP) fertilizer.

- GreenSwitch® Nitrate is manufactured using Pure Green Agriculture technology, the world’s first patented process for turning manure into liquid nitrate fertilizer for the high-tech greenhouse sector and open-field fertigation. The innovative production process generates a pure and transparent liquid nitrate end-product with a carbon footprint that is close to zero.

- Plants for Plants® are plant-based biostimulants derived from cultivated crops. This new biostimulants range is suitable for organic and conventional agriculture and was developed by Plants for Plants, a project funded by the EU’s LIFE research programme.

Baseline carbon footprint

As a starting point, Van Iperen decided to benchmark its carbon footprint for the year 2021 to provide an accurate baseline for reducing emissions in future years. This footprint encompassed all of the company’s activities and the products it sells, using calculations based on credible and transparent databases such as ecoinvent to fully map its business impacts.

Van Iperen calculated the contribution to its carbon footprint of every process and activity behind all of its end-products. This thorough and comprehensive analysis included the impacts associated with the upstream production of raw materials sourced from its suppliers, as well as the impacts of the downstream delivery of products to customers/distributors by road haulage in trucks and by shipping container. (Note that the impacts of product deliveries from distributors to growers were not included.)

Main carbon emission sources

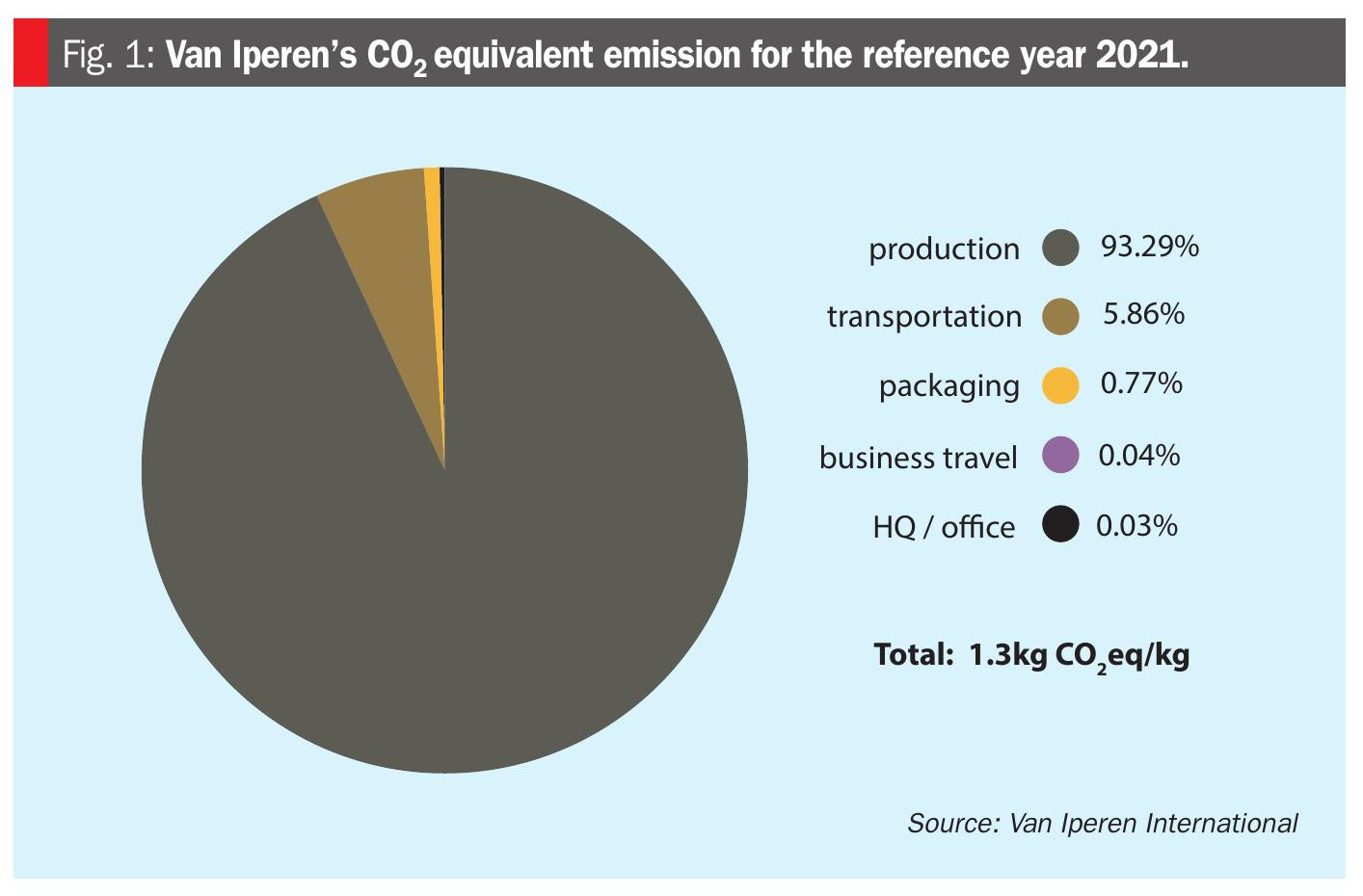

Van Iperen identified four main categories of carbon emissions resulting from its business activities – production, transportation, packaging, and office and travel. Emissions for each of these four categories were calculated to determine their individual contributions to total emissions.

The company reported its carbon footprint for the reference year 2021 (1.3 kg CO2 eq / kg) on a total emissions per kilogram of fertilizer sold basis (Figure 1). It was decided that this was a more relevant metric as, being a growing company, Van Iperen’s absolute CO2 emissions will be heavily affected by the total quantity of fertilizers it supplies to the market in any given year.

Carbon footprint findings and results for the four main categories were as follows:

1. Production: Mineral fertilizer manufacturing is generally known to be energy-intensive and have a high carbon footprint, with Van Iperen’s production processes being no exception. This category includes estimated carbon emissions of all the fertilizers products sold by Van Iperen in the reference year, whether from in-house production or those associated with products and raw materials sourced from third parties (embodied emissions). This category, unsurprisingly, represents the largest proportion of the company’s carbon footprint by far, accounting for 93.29% of total emissions. This underlines the production decarbonisation challenge facing the fertilizer industry and the need to prioritise this in future.

2. Transportation: This is Van Iperen’s second-largest emissions source, accounting for 5.86% of the company’s total footprint. It includes the transportation of raw materials from suppliers to production plants, as well as the onwards transportation of products to customers. It therefore includes both upstream and downstream transport emissions by sea and road.

3. Packaging: Van Iperen’s third largest emissions source is packaging, which surprisingly – says the company – only accounted for 0.77% of its carbon footprint. This category includes the embodied emissions of all types of product packaging, such as bottles, cans, boxes, bags, and labels, as well as pallets. Reducing plastic packaging waste was identified as a priority by the company due to its potential for environment pollution as well as its carbon impacts.

4. Office and Travel: This final category represents just 0.07% of the total footprint, being divided between the impacts of running the company office (0.03%) and business travel (0.04%), the latter including office employee travel and international visits to partner businesses. Emissions from business travel in 2021 were, however, lower than normal as employees were mainly working from home due to the Covid-19 pandemic.

COMMITTED TO SUSTAINABILITY

Van Iperen International is currently implementing the EU’s Corporate Sustainability Policy Directive (CSRD). This aims to improve and standardise sustainability reporting across the region’s companies, based on environmental, social, and governance (ESG) goals.

“By adopting the CSRD, we are committed to transparency and accountability in our sustainability practices – we will start reporting in January 2026,” Marine Lair, the company’s Director of Marketing, told Fertilizer International. “Right now, we are fully focused on preparing for this, ensuring we can accurately measure our ESG progress and identify areas for improvement.”

Marine was also keen to emphasise the role of specialty fertilizers in the company’s Green Switch Journey.

“Specialty fertilizers, such as water-soluble products for drip irrigation and foliar applications, offer practical benefits by enabling precise nutrient application, reducing leaching and evaporation, and improving uptake efficiency,” Marine said. “Our range of high performing products – by promoting water use efficiency and nutrient use efficiency – are also part of our sustainability journey.”

Erik van den Bergh, Van Iperen’s Managing Director (pictured), summed up the company’s aims and ethos:

“Sustainability is something that everybody speaks about. But how to make it really a win, not only for the planet but also for all the actors involved? That is the challenge.”

What concrete actions is Van Iperen taking?

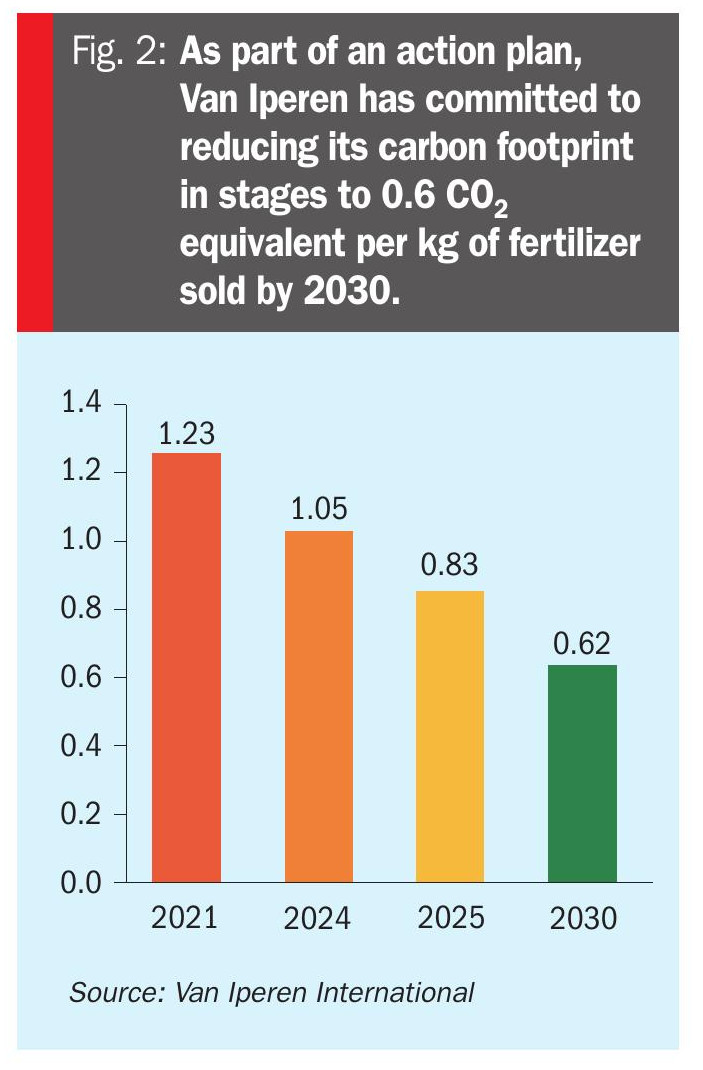

Van Iperen’s emissions in 2021 totalled 1.3 kg CO2 equivalent per kilogram of fertilizer sold – a level the company has committed to bringing down in the years ahead.

Following the benchmarking of its carbon footprint, the company published updated business and action plans, with these including a clear target to reduce Van Iperen’s carbon footprint per kg of product sold by more than 50% by 2030. In practice, this means reducing its footprint in stages to 0.6 CO2 equivalent per kg of fertilizer sold (Figure 2).

Van Iperen will report on progress towards this target in its annual reports – and says it will act more quickly if actions to speed up carbon cutting to meet the 2030 target are identified.

Achieving dramatic carbon reductions will require action in a number of key areas. This notably includes developing new technologies to produce greener, more sustainable fertilizers and bring these to the market for high-tech farming.

“Our GreenSwitch® Nitrate and Green-Switch® Potassium are two innovative production processes that use organic sources or by-products with a close to zero carbon footprint,” comments Van Iperen. “These processes have resulted in the creation of two new fertilizers: GreenSwitch® Original HG, which is the first liquid nitrate fertilizer from an organic source, and GreenSwitch® SOP, the first potassium sulphate fertilizer using by-products of recycling industries.”

The introduction of these product lines is instrumental to driving down the company’s average carbon footprint per kg fertilizer sold. Indeed, Van Iperen has plans to introduce other new fertilizers under the GreenSwitch flag in the near future – to allows growers to practice sustainable crop nutrition without any compromise on yield and quality.

2024 progress update

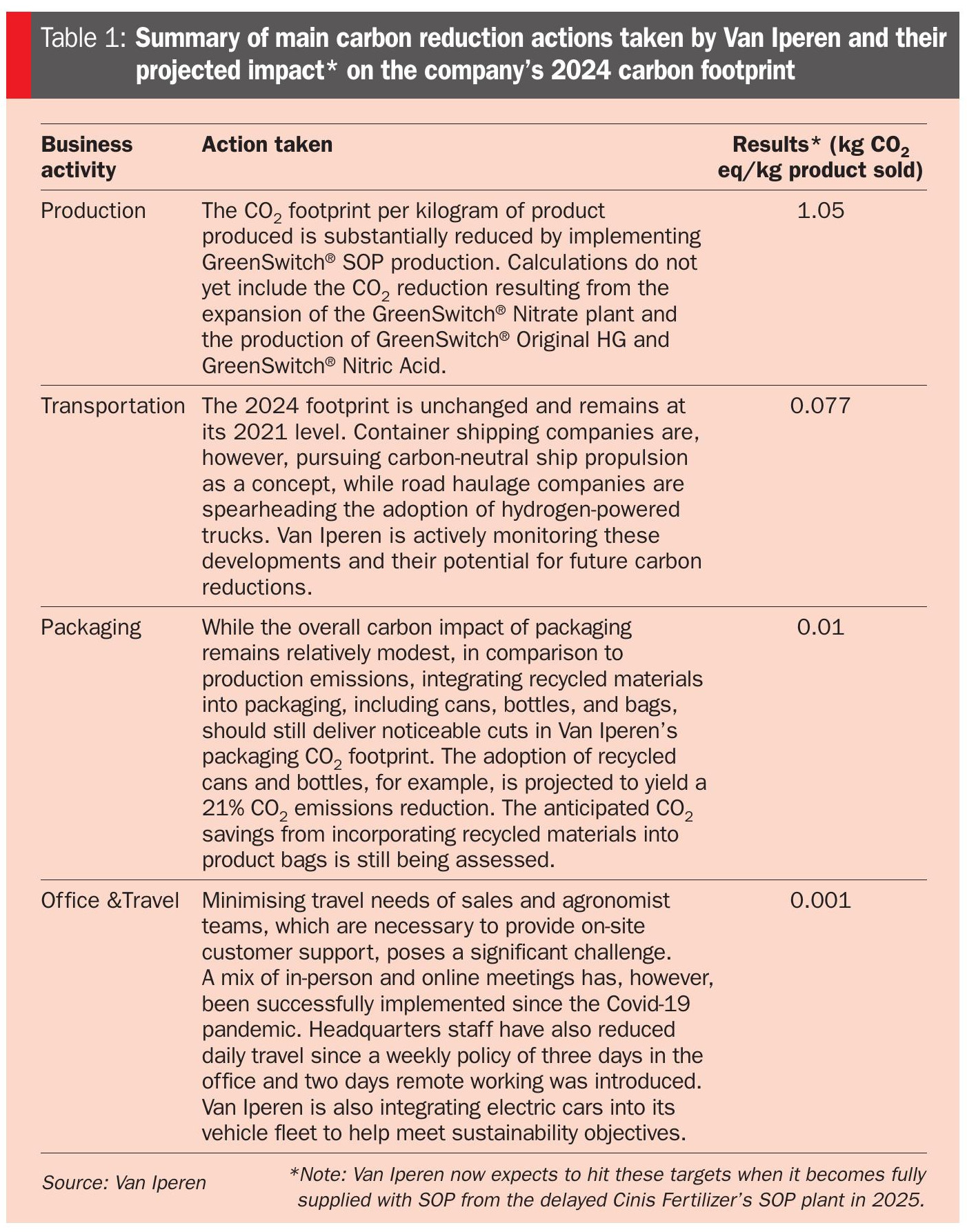

Van Iperen made concerted efforts during 2022 and 2023 to address the various underlying factors responsible for its carbon footprint. Details of the actions taken for various business activities, alongside projected CO2 footprint for 2024, are shown in Table 1.

Results show the potential for substantial carbon reductions from the implementation of GreenSwitch® technology. Furthermore, while the results in Table 1 show the positive impact GreenSwitch® SOP production can make, they do not yet include CO2 reductions resulting from the expansion of the GreenSwitch® Nitrate plant. This unit will produce low-carbon GreenSwitch® Original HG and GreenSwitch® Nitric Acid products in future.