Sulphur 413 Jul-Aug 2024

31 July 2024

Middle East Sulphur Conference 2024

CONFERENCE REPORT

Middle East Sulphur Conference 2024

Representatives from across the global sulphur and sour gas community convened in Abu Dhabi from 20 to 23 May to discuss and debate the key strategic themes that are driving the industry. The Middle East Sulphur Conference (MEScon) is a premier event that brings together representatives from the entire sour gas and sulphur value chain to promote technology and innovation, lessons learned, best practices, knowledge transfer and R&D.

The Middle East Sulphur Conference 2024, organised by CRU and UniverSUL Consulting and hosted by ADNOC, returned to the Conrad Abu Dhabi Etihad Towers for this premier sulphur event in the region which has become the epicentre of global sulphur and sour hydrocarbon production.

Day 1

This year’s programme introduced some key new features on Day 1 of the conference, which is reserved for pre-conference workshops and interactive sessions.

MEScon Operations Roundtable

The MEScon Operations Roundtable was kicked off with an opening message from Angie Slavens, UniverSUL Consulting, who welcomed delegates and mentioned that this event is a throwback to the annual MESPON Operations Roundtable but done a little differently. The roundtable was chaired by Elmo Nasato, Nasato Consulting, and supported by industry experts from Amine Experts, ASRL, Axens, BASF, DuBois Chemicals, Enersul, Euro Support, and Worley Comprimo. The session promoted an open exchange of ideas, encouraging participants to share their operational experiences and challenges in the areas of gas treating, sulphur recovery, tail gas treating, sulphur forming and handling, and CO2 capture. Each topic introduction by the panelists was followed by an open forum Q&A, fostering a collaborative atmosphere where attendees could learn from one another.

In addition to technical insights, the roundtable offered valuable networking opportunities. Conducting the session at the beginning of the event provided an opportunity for participants to identify key individuals to connect with over the course of the four day conference, presenting the opportunity to foster professional relationships and potential collaborations. The rich discussions and exchange of operational experiences ensured that delegates left with actionable insights and practical information to apply to their own facilities. The collaborative environment and expert-led sessions were instrumental in addressing current industry challenges and exploring innovative solutions, making the MEScon Operations Roundtable a success that is likely to be repeated in future years.

MEScon Sulphur Youth Majlis Session

The Sulphur Youth Majlis Session was a specially designed event aimed at inspiring and guiding young professionals, under the age of 38, as they explore career paths within the sour gas treating and sulphur industries. This session focused on fostering meaningful connections, providing valuable insights, and equipping attendees with the necessary tools for successful careers in sulphur. The session was initiated with a welcome message from Nasser Al Busaeedi, SVP of ADNOC Gas, who emphasised the importance of youth development in ADNOC, as well as the importance of sulphur to the organisation. A scavenger hunt then ensued, which served as an ice breaker to get people engaged and interacting with one another. When participants returned to the room, the Youth Panel was conducted, featuring up-and-coming young professionals in the industry: Al Sail Al Jaberi from ADNOC Sour Gas, Maryam Al Marzooqi from ADNOC Gas, Bader Alotaibi from Aramco, Feras Kordi from BASF, and Mahmoud Shafy from HEC. These individuals shared their career journeys, discussing what they love about their current roles, the challenges they face, their aspirations if failure was not an option, and the tools they believe are necessary for achieving their career goals.

Following the Youth Panel, an Expert Panel session, comprised of seasoned professionals with diverse career paths, was conducted. The panel included Mohamed Ashraf from Systems & Equipment, who discussed his entrepreneurial path; Rashed Bametraf from ADNOC Gas, who focused on technical operations; Rob Marriott from ASRL, who shared insights from an academic perspective; Elmo Nasato from NCL, who talked about innovation and R&D; Angie Slavens from UniverSUL, who addressed techno-commercial careers; and Ravi Srinivas from ADNOC Sour Gas, who discussed technical design. These experts provided insights into their career motivations, shared stories of influential mentors, and offered advice to young professionals in the sulphur industry.

Following the panel discussions, an engaging open forum Q&A allowed attendees to actively participate by asking questions and sharing their thoughts. Overall, the Sulphur Youth Majlis Session successfully inspired young professionals, provided them with valuable career guidance, and facilitated networking opportunities crucial for their professional growth in the sour gas and sulphur industries.

Aisha Alkayyoomi and Fatima Aldhaheri of ADNOC Sour Gas won the scavenger hunt prize, collecting all six correct answers in the shortest amount of time.

Arthur vas Asbeck of Paqell won the prize for best pipe cleaner sculpture with his H2 S molecule.

BR&E Carbon Capture in the Sulphur Value Chain Workshop

BR&E’s Ganank Srivastava and Mostafa Shehata conducted a reservation-only workshop session which reviewed the complete process flow of a sour gas plant, representative of the Middle East landscape. The workshop explored opportunities for implementing CO2 capture plants along this value chain utilising BR&E’s simulation tools. The workshop was fully subscribed, with around 40 attendees, who found it provided them with an interesting and unique perspective on the sulphur value chain.

Technical Showcases

Chaired by Frank Scheel, Worley Comprimo, this year’s Technical Showcase session highlighted innovative advancements in the sulphur industry. Leorelis Vasquez and Nathan Smith from Worley Comprimo discussed carbon capture options for gas processing plants, focusing on reducing emissions and enhancing sustainability. Jan Kiebert from Sulphur Experts presented on the technical aspects of sweeping and shutting down sulphur recovery units (SRUs) through the tail gas treating unit (TGTU), emphasising plant longevity and operational efficiencies. Arthur van Asbeck from Paqell introduced developments in the Thiopaq O&G process, showcasing the use of biotechnology for more efficient sulphur recovery. Johann Le Touze from Axens presented the CRS 41 catalyst, explaining how its low-density TiO2 composition improves sulphur recovery efficiency. Finally, Majed Qaysi from Aramco highlighted orbital shaft machining technology for sulphur pelletisers, which enhances precision and durability.

The session concluded with an engaging Q&A, allowing attendees to interact with the presenters and explore the innovations further.

Day 2

Day 2 marked the official opening of MEScon 2024. More than 650 delegates, representing 76 companies from 25 countries from across the sour gas and sulphur value chain, were welcomed through the doors of the Conrad Abu Dhabi Etihad Towers.

The event kicked off with opening speeches from ADNOC and Aramco, the two largest sulphur-producing companies in the world. Abdullah Al Messabi, CEO ADNOC Sour Gas, welcomed delegates on behalf of ADNOC, followed by Ahmed M. Al Wadeai, Director of Berri Gas Plant, who delivered Aramco’s welcome. Both executives emphasised the importance of sulphur to their companies now, and in the future.

Fahad Al Wahedi, SVP & MEScon Executive Chairman, ADNOC Upstream, officially welcomed delegates to the MEScon 2024 event, followed by a MEScon kick-off presentation from Angie Slavens, UniverSUL Consulting and Al Sail Al Jaberi, ADNOC Sour Gas, who indicated that this event marks ten years of sulphur conferences in Abu Dhabi (between predecessor events MESPON and Middle East Sulphur – now combined to form MEScon). Key presentations in the morning session included an energy outlook by Michael Nevin, COO of io consulting, and a sulphur market overview by Dr Peter Harrisson, Principal Analyst at CRU. Other highlights of the morning session included insights on the new Hail & Ghasha Sour Gas Plant in UAE, the Tanajib Gas Plant in KSA, and Element 16’s sulphur thermal energy storage technology, including a pilot project in Oman.

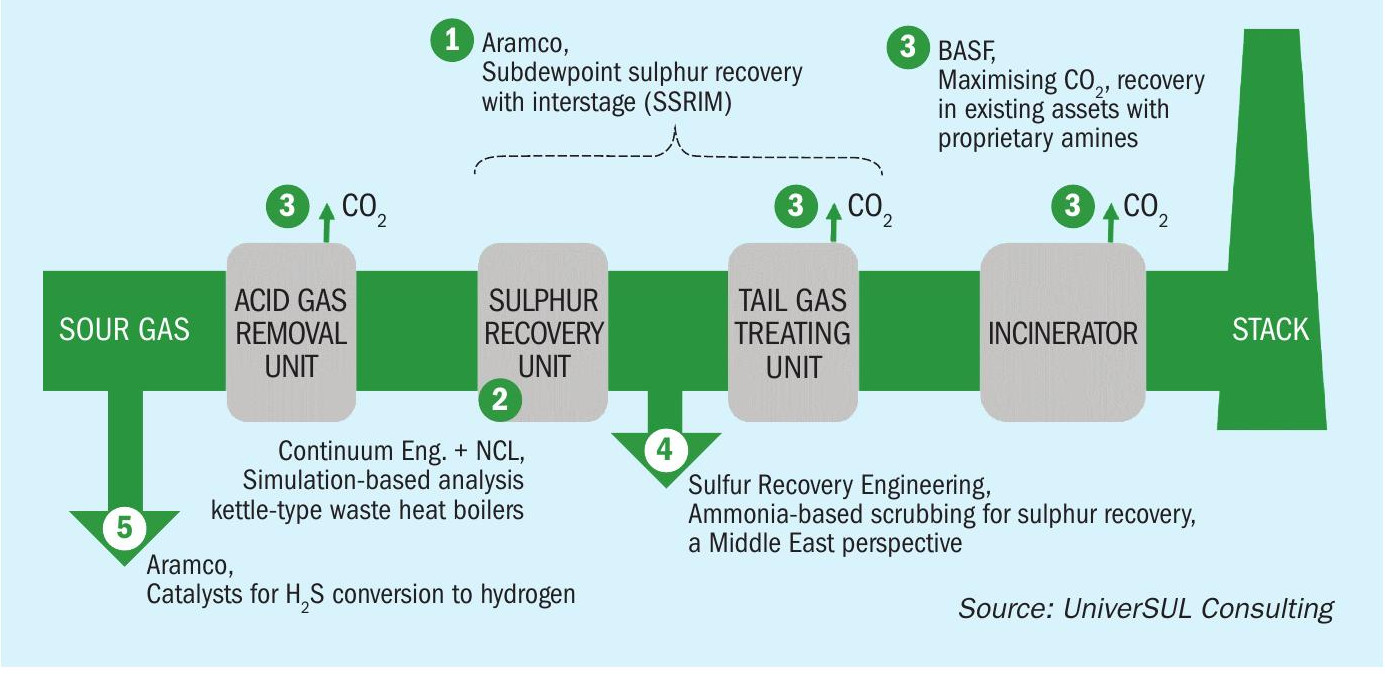

The afternoon took a look at novel approaches toward sour gas processing and sulphur recovery in the ‘Innovative sour hydrocarbon strategies, technologies and design approaches’ session. The paper topics presented in this session are shown in the graphic in Fig. 1. John O’Connell, Aramco, kicked off the session with a review of Aramco’s SSRIM technology, which is aimed at achieving improved sulphur recovery for the subdewpoint process. Nasser Abukhdeir, Continuum Engineering, and Elmo Nasato, NCL, then presented an innovative approach toward evaluating the water side of SRU WHBs. Ashraf Abufaris and Feras Kordi, BASF, then presented a case study on recovering CO2 from existing assets utilising OASE solvents. Following the afternoon break, Inshan Mohammed, SRE, presented an evaluation of ammonia-based tail gas treating technology. Aramco’s Anton Manakhov wrapped up the session with a presentation describing Aramco’s development of a catalyst designed to convert H2S to H2.

The day wrapped up with the daily quiz, which was won by Johann Le-Touze of Axens.

Day 3

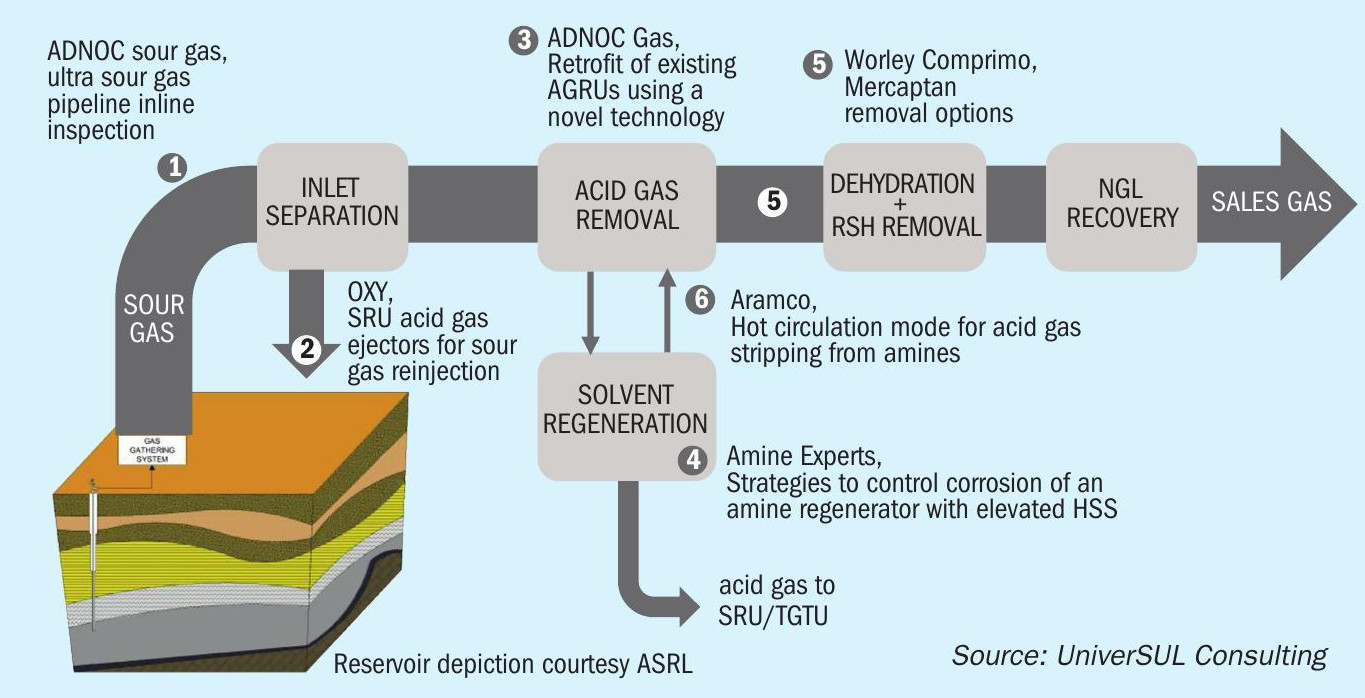

Day 3 began with a flurry of new participants eager to join the morning deep dive into gas treating in the ‘Gas treating excellence from wellhead to SRU’ session, which was moderated by Dr Rob Marriott, ASRL. The paper topics presented in this morning session are shown in the graphic in Fig. 2. Saeed Al Bloohshi, ADNOC Sour Gas, kicked off the session with insights into sour gas pipeline inspection procedures at Shah. Oxy’s Seth Spear then presented a novel approach to acid gas injection using ejectors. Ibrahim Khan, ADNOC Gas, then described recent efforts to improve acid gas removal operations at Habshan by enhancing mass transfer in the absorber. Ben Spooner, SGS Amine Experts, shared an interesting case study to prolong the life of an existing amine regenerator which was experiencing high corrosion rates due to heat stable salts. Worley Comprimo’s Jon Lewis then gave a talk on mercaptan removal options and Aramco’s Bader Alotaibi wrapped up the session with an innovative approach to stripping amine of H2S prior to shutdown.

Prior to lunch, a Poster Spotlight was conducted, allowing all poster presenters to give a five minute brief on their digital posters which were presented on monitors during the exhibition. Four posters by Aramco and one poster by AIMS were presented during this session. Participants crowded around the speakers in the exhibition area during breaks to listen intently about their case studies, an opportunity for the audience to learn directly from operating and supplier companies.

The afternoon session took a look at digitalisation and automation advances in the ‘Sulphur Industry 4.0’ session, which was moderated by Yasin Al Awadhi of ADNOC. Topics on AI, machine learning, automation, digital dashboards, and linking simulation with plant data were presented by ADNOC Gas, Aramco and BR&E. An audience poll conducted during this session indicated that the audience believes the Middle East is farther along in implementation of these types of tools in sulphur plants than are other parts of the world.

The daily quiz was won by John O’Connell of Aramco.

Day 4

The final day of the conference saw strong attendance, with participants eager to engage in discussions related to sulphur handling and best practices in SRU/ TGTUs. Opening remarks were provided by Ahmed Basioni, SVP of ADNOC Sour Gas.

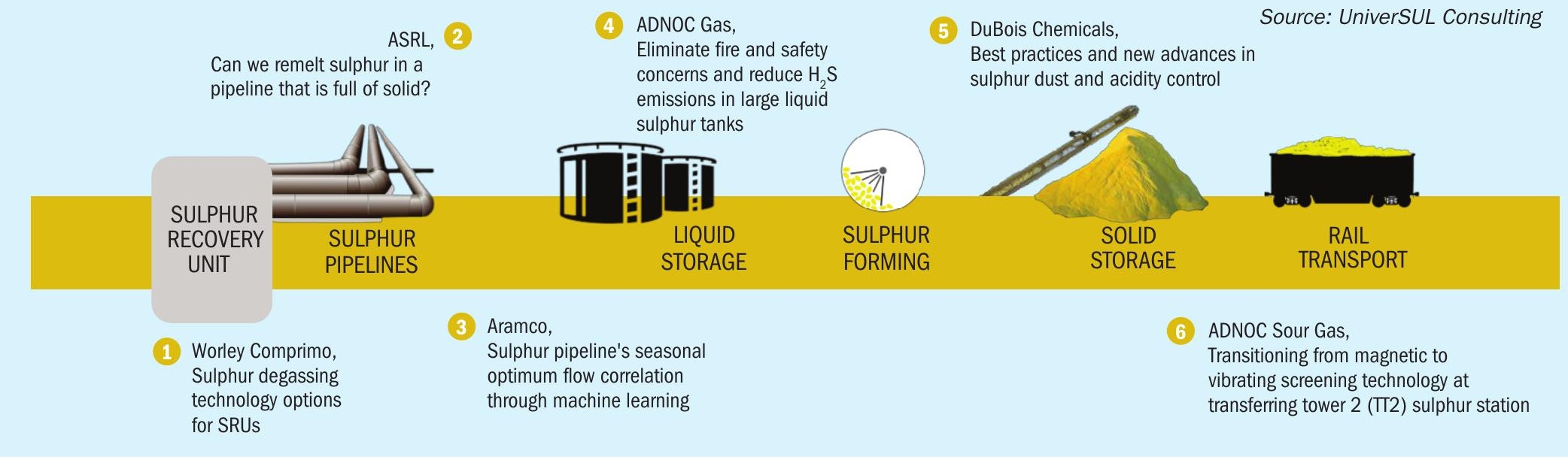

Angie Slavens of UniverSUL Consulting mentioned that the opening session ‘Sulphur handling experience from the world’s largest producing region’ is special in this part of the world because it is one of the only places where we can take a deep dive into all steps of the sulphur forming and handling process due to the large number of massive sulphur handling facilities in the region. The session (see Fig. 3 for overview) was chaired by Saood Al Marzooqi, ADNOC Sour Gas and covered topics from sulphur degassing (Marco van Son, Comprimo), sulphur pipeline remelt (Dr Rob Marriott, ASRL), sulphur pipeline seasonal optimum flow (Bader Alotaibi, Aramco), sulphur tank venting best practices (Pankaj Kumar, ADNOC Gas), advances in sulphur dust and acidity control (Jeff Cooke, DuBois Chemicals), and magnetic vs. vibrating screening at Shah’s complex (Mohammed Al Booshi, ADNOC Sour Gas).

Poster spotlights were presented by Aramco, ADNOC Sour Gas and BR&E, once again showcasing a wide range of operations topics which allowed delegates to hear case studies and lessons learned directly from the field.

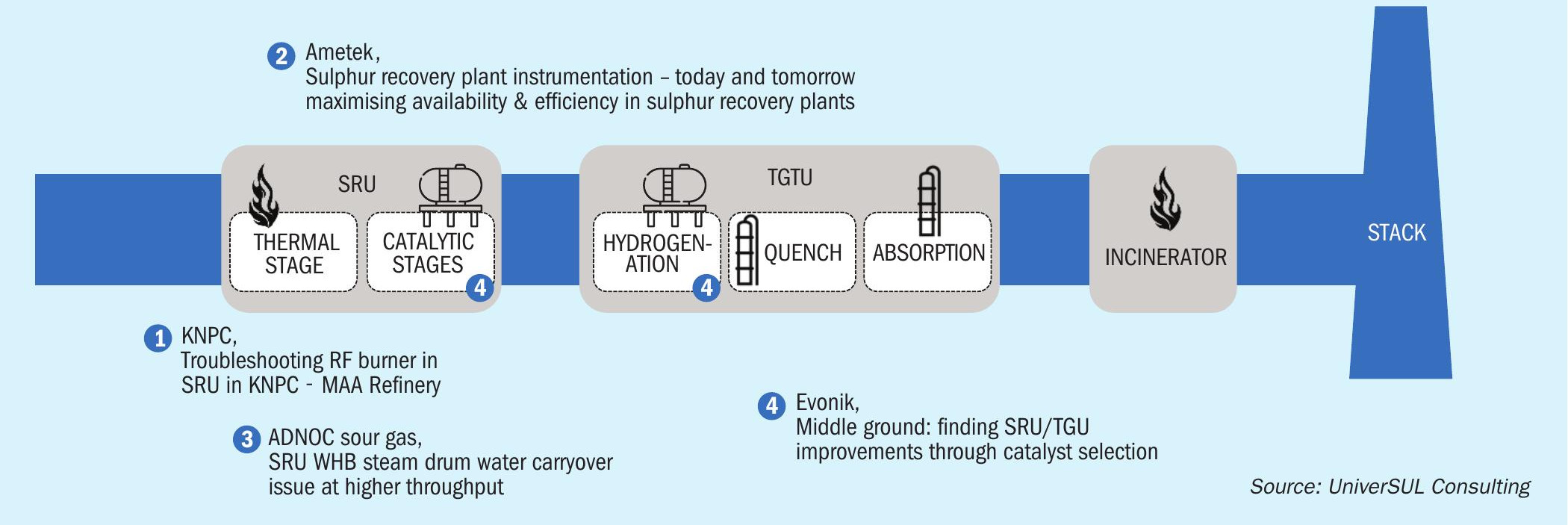

After lunch, the final session on ‘Best practices in SRU/TGTU operation and design’ was chaired by Elmo Nasato, Nasato Consulting, and comprised four papers (Fig. 4). KNPC’s Saad Almutairi kicked off the session with a presentation on troubleshooting an SRU burner at the KNPC MAA Refinery. Ametek’s Jochen Geiger then gave an historical account of the developments in SRU/TGTU analysers and suggestions for modern best practices. Muhammad Nisar of ADNOC Sour Gas discussed challenges related to water carryover from their WHBs at higher than design acid gas feed rates and Evonik’s Brian Visioli wrapped up the session with a presentation on the optimum, holistic approach to evaluating catalyst requirements.

The final daily quiz was won by Rashid Rajhi of PDO and scavenger hunt prizes were awarded to Ayesha Alkayoomi of ADNOC Sour Gas (1st place) and Shailesh Dayal of Blasch (2nd place).

Adel Al Jaberi, SVP ADNOC Sour Gas, gave the closing remarks, thanking delegates and participants and expressing ADNOC’s continued commitment to the event.

Attendees representing 25 countries gathered at MEScon 2024.