Sulphur 414 Sep-Oct 2024

30 September 2024

Sulphur + Sulphuric Acid 2024 Conference

CONFERENCE + EXHIBITION PREVIEW

Sulphur + Sulphuric Acid 2024 Conference

Join us at the CRU Sulphur + Sulphuric Acid 2024 Conference and Exhibition in Barcelona, 4-6 November, for a global gathering of the sulphur and sulphuric acid community. Meet leading market and technology experts and producers, network, share knowledge, and learn about market trends and the latest developments in operations, process technology and equipment.

The Sulphur + Sulphuric Acid 2024 Conference and Exhibition takes place at the Hyatt Regency Barcelona Tower in Barcelona 4-6 November. This year marks the 40th year of the Sulphur conference and features the most comprehensive agenda yet.

The opening session of the main agenda brings together industry leaders to discuss sustainability initiatives and strategies for decarbonising the sector. Focusing on the integration of digitalisation, strategic advancements in production, and global collaboration, this session aims to shape a more sustainable and efficient sulphur and sulphuric acid supply chain, crucial for the evolving green economy.

The market outlooks agenda has been extended with expert insights from CRU’s analysis teams on major supply and demand markets, including sulphur and sulphuric acid, plus additional industry updates from key players from across the supply chain.

On the agenda this year, leading producers from around the globe, alongside technology and technical experts will be sharing operational best practices and insights to improve plant operations. The comprehensive technical programme is split into two parallel streams, a sulphur track and a sulphuric acid track, and will provide updates on the production and processing of sulphur and sulphuric acid, with presentations covering new innovations in processes, technology, materials and equipment developments, as well as practical case studies highlighting operational experience and improvements. Sulphur and sulphuric acid troubleshooting clinics, panel discussions and technical showcases will extend the opportunities to learn about best practices, lessons learned and the latest technologies and innovations.

This year’s conference will once again be co-located with RefComm Europe.

Preliminary Agenda

Monday, 4 November

SULPHUR TRACK – 10:00-13:45

10:00-12:00 – Sulphur Troubleshooting Clinic

Presenter: Elmo Nasato, Nasato Consulting Ltd

12:30-13:45 – Technical Showcases

- Rejuvenation of a vintage SRU to meet hanging refinery requirements – Claudio Pupatti, Wood

- Two big advancements in Claus instrumentation – Bob Poteet, WIKA

- Eliminating nitrogen purging in SRU furnaces: Daily ImpermaWell™ and its benefits for process optimisation and safety – Deniz Keles, Daily Thermetics

- Technological solution for designing customised products from liquid and powdered raw materials – Johannes Buchheim, Glatt Ingenieurtechnik GmbH

- Flexible mechanical drives for fans and compressors – Cornelia Liebmann, Howden

SULPHURIC ACID TRACK – 10:00-13:45

10:00-12:00 – Sulphuric Acid Troubleshooting Clinic

Presenters: Stuart Hinze, J.R. Simplot Company; Hanno Hintze, Aurubis AG; Hannes Storch, Metso; Steve Puricelli, EXP

12:30-13:45 – Technical Showcases

- Spray solutions for sulphur and sulphuric acid – Sebastian Rohacz, Lechler GmbH

- Practice of technical reformation of dry absorption and water addition of sulphuric acid plant – Jae Shi, Wylton (China) Chemical Co., Ltd

- Leak detection and dew point measurement in sulphuric acid plants – Cal Lockert, Ohio Lumex Co., Inc.

- Optimising wear life and performance in sulphuric acid production – Dr. Carsten Düchting, DÜCHTING Pumpen Maschinenfabrik GmbH & Co. KG

- Gain and retain talent with our proven on-line courses for sulphuric acid plant operators – Dirk van der Werff, Academia.Holtec

COMMERCIAL AND MARKETS SESSION –14:00-17:30

Welcome address

- Special guest key note address – Prof. Dr. rer. nat Christian Sattler, German Aerospace Center

- Panel discussion: Sulphur and sulphuric acid industry – At the heart of the future green economy – Chair: Hannes Storch, Metso Outotec – Speakers: Khalid Hamed Al-Ahmadi, Ma’aden; Lucretia Löscher, thyssenkrupp Uhde; Dr Sascha Vukojevic, BASF; Francesca Ortolan, CEFIC; Graeme Cousland, Begg Cousland Envirotec Ltd

- Focus on sulphur and sulphuric acid – Peter Harrisson, CRU

- Panel discussion: Sulphur and sulphuric acid industry economics – Future strategy, production, markets and global trading Chair: Peter Harrisson, CRU – Panellists: Craig Jorgenson, The Sulphur Institute; Viviana Alvarado, CRU; Jérôme Villaumie, Sojitz-Solvadis; Janne Lovén, Boliden Smelters

WELCOME RECEPTION –17:30-19:00

Tuesday, 5 November

SULPHUR TRACK – 09:00-12:30

Sulphur plant reliability, availability, maintenance & economics

- Initiatives at sulphur recovery unit (SRU) to reduce and eliminate hotspots due to refractory failures – Mukhriz Badaruddin, Petronas

- European SRU incinerators -Optimising to simultaneously save money and reduce CO2 emissions – Leah Goettler, Sulphur Experts

- Considerations for reliability, safety, and operations responsibilities during extended downtime – Baylee Thompson, Wood

- How enhanced reality technology increases operator competency and reduces human error – Susanna Voges, Bas Janssen, Voovio

- You can’t always get what you want (but you can get what you need!) – Steve Puricelli, EXP

- Panel discussion: Sulphur plant reliability, availability, maintenance & economics – Panellists: Mukhriz Badaruddin, Petronas; Leah Goettler, Sulphur Experts; Baylee Thompson, Wood; Susanna Voges and Bas Janssen, Voovio; Steve Puricelli, EXP

SULPHUR TRACK – 13:30-17:30

Sulphur plant operational best practices

- Minimising amine carryover from a regenerator – Ben Spooner, Amine Experts

- Alkanolamines in the thermal reactor as a possible source of ammonia – Rob Marriott, ASRL

- Kuwait Oil Company’s approach to sustainable oil recovery: Addressing sulphur-induced iron sulphide formation in effluent water treatment – Mahdi Ashkanani, Kuwait Oil Company

- Advanced feed gas control by detecting the BTEX concentration in sulphur recovery units (SRUs) – Michael Gaura, Ametek

- Risk of accumulated sulphur in sulphur recovery unit – Ganesh Gujar, Bharat Petroleum Corp. Ltd

- Thermodynamic simulation and case study for 3rd generation SRU incinerator – Mason Lee, Aecometric Corp.

- Low temperature activation of 934 catalyst at Motiva Port Arthur: Assessment of staged addition of H2S and H2 – Ron Pitman, Motiva

SULPHURIC ACID TRACK – 09:00-12:30

Sulphuric acid industry innovation: Digitalisation, energy transition, circular economy

- Using AI-powered infrared imaging for real-time sulphur dioxide leak detection and quantification – Francisco Cortez, SENSIA Solutions

- Implementation of low CO2 district heating usage of copper smelter’s sulphuric acid plant – Hanno Hintze, Aurubis AG and Torsten Weber, Smart SCOPE GmbH

- Utilisation of non-condensable gases from pulp and paper process – Robert Kahr, Kanzler Verfahrenstechnik GmbH

- Supporting decarbonisation with new approaches in the sulphuric acid industry – Dimitrios Dimitrakis, Deutsches Zentrum für Luft und Raumfahrt (DLR) and Martin Kürten, Grillo Chemicals GmbH

- Advances in NOx removal in a metallurgical DCDA/Petersen Fattinger process – Anthony McHendrie, Anglo American Platinum

- Panel discussion: Sulphuric acid industry innovation: Digitalisation, energy transition, circular econom – Panellists: Dimitrios Dimitrakis, Deutsches Zentrum für Luft und Raumfahrt (DLR); Martin Kürten, Grillo Chemicals GmbH; Anthony McHendrie, Anglo American Platinum

SULPHURIC ACID TRACK – 13:30-15:00

Sulphuric acid plant performance: Catalysts and emissions

- Staying ahead of todays and future SO2 emission limits – Why superior catalyst shape and composition is so important – Jochen Willersinn, BASF SE

- Understanding the sulphuric acid catalyst properties and reaction resistance in the SO2 oxidation – and their implications for catalyst design and selection – Martin Alvarez, Anders Theilgaard Madsen, Topsoe A/S

- Platinum promoted honeycomb catalysts for sulphuric acid making -A novel approach for CAPEX and OPEX reduction in acid plants – Johannes Hofer, P&P Industries AG

- Panel Session: Sulphuric acid plant performance: Catalysts and emissions – Panellists: Jochen Willersinn, BASF SE; Martin Alvarez, Anders Theilgaard Madsen, Topsoe A/S; Johannes Hofer, P&P Industries AG

SULPHURIC ACID TRACK – 15:30-17:30

Sulphuric acid plant operations: Debottlenecking, reliability & availability

- How to successfully run a four-year acid plant campaign – Trevor Mwanza, Kansanshi Mining Plc

- Digital solutions to improve operational KPI’s and increase plant availability for gas cleaning and sulphuric acid plants – Steffen Haus, Metso

- Increase plant No. 7 reliability and stability – Ayman Abdelhafeiz, Abu Zaabal Fertilizer & Chemical Company

- Capacity and uptime boost: Optimising sulphuric acid plant from 2200 to 3000 MTPD – Florian Kistl, CS Combustion Solutions GmbH

DRINKS RECEPTION –17:30-18:30

Wednesday, 6 November

SULPHUR TRACK – 09:00-13:00

Innovation, digitalisation & energy optimisation in the sulphur plant

- H2S splitting industrial units – Giovanni Manenti, ITT SpA

- Energy and cost optimisation opportunities in an SRU – Jan Willem Hennipman, Worley Comprimo

- The Digital Process Monitor (DPM): Digitalisation aiming to process and environmental excellence – Daniela Boni, Nextchem Tech

- A step-by-step approach to reducing CO2 through SRUs – Samuel Scherman Johansson, Topsoe A/S

- Probabilistic, time-based economic analysis of sulphur recovery technologies – Alberto Martinez, Worley Comprimo; Harry Matthews, Indicatura

- Panel Session: Innovation, digitalisation & energy optimisation – Panellists: Giovanni Manenti, ITT SpA; Jan Willem Hennipman, Worley Comprimo; Daniela Boni, Nextchem Tech; Samuel Scherman Johansson, Topsoe A/S; Alberto Martinez, Worley Comprimo; Harry Matthews, Indicatura

- Open Forum Q&A / War Stories

SULPHUR TRACK – 14:00-16:00

Sulphur product handling safety, innovation & best practices

- Safety in design of sulphur forming and handling – David Savage, Matrix Service Company

- Exploring other sulphur sources and ways of purification – Jan Hermans, Sulphurnet

- Sulphur degassing for large scale sulphur recovery units – Marcus Weber, Fluor

- Panel Session: Sulphur product handling safety, innovation & best practices – Panellists: David Savage, Matrix Service Company; Jan Hermans, Sulphurnet; Marcus Weber, Fluor

SULPHURIC ACID TRACK – 09:00-11:00

Sulphuric acid plant design: Process technologies

- Enhancing sulphur burning acid plants with oxygen-enriched air: LUREC-S – Stefan Bräuner, Metso

- The CORE-FGD™ process in action -Producing sulphuric acid from gas streams with low SO2 concentrations – Boris Nesic, Worley Chemetics

- Oxygen plant compressor electricity savings and CO2 reduction using new technology actuators on compressor inlet guide vanes – Mark Ferra, REXA Inc.

- Production of liquid SO2 via condensation – synergies with sulfuric acid manufacturing and challenges of energetic optimisation – Dr. Daniel Fickinger, HUGO PETERSEN GmbH

- Panel Session: Sulphuric acid plant design: Process technologies – Panellists: Stefan Bräuner, Metso; Boris Nesic, Worley Chemetics; Mark Ferra, REXA Inc.; Dr. Daniel Fickinger, HUGO PETERSEN GmbH

SULPHURIC ACID TRACK – 11:30-13:00

Sulphuric acid plant design: Equipment

- Steuler quickfit brick-lined equipment delivered ready for fast installation – Rolf Rockenmayer, Steuler Tecnica s.l.u.

- Outstanding accuracy and no acid-runaway: Inline concentration monitoring of sulfuric acid with LiquiSonic® – Alexandra Graf, SensoTech GmbH

SULPHURIC ACID TRACK – 14:00-16:00

Sulphuric acid plant design: Equipment

- Sulphur pit scrubber – Alessandro Gullà, AWS Corporation Srl

- Ducting design for sulphuric acid plants – Robert Cane, NORAM Engineering and Constructors

- Anton Paar’s inline measurement solutions for sulphuric-acid and oleum – Emanuel Hofer, Anton Paar GmbH

- Panel Session: Sulphuric acid plant design: Equipment – Panellists: Alessandro Gullà, AWS Corporation Srl; Robert Cane, NORAM Engineering and Constructors; Emanuel Hofer, Anton Paar GmbH

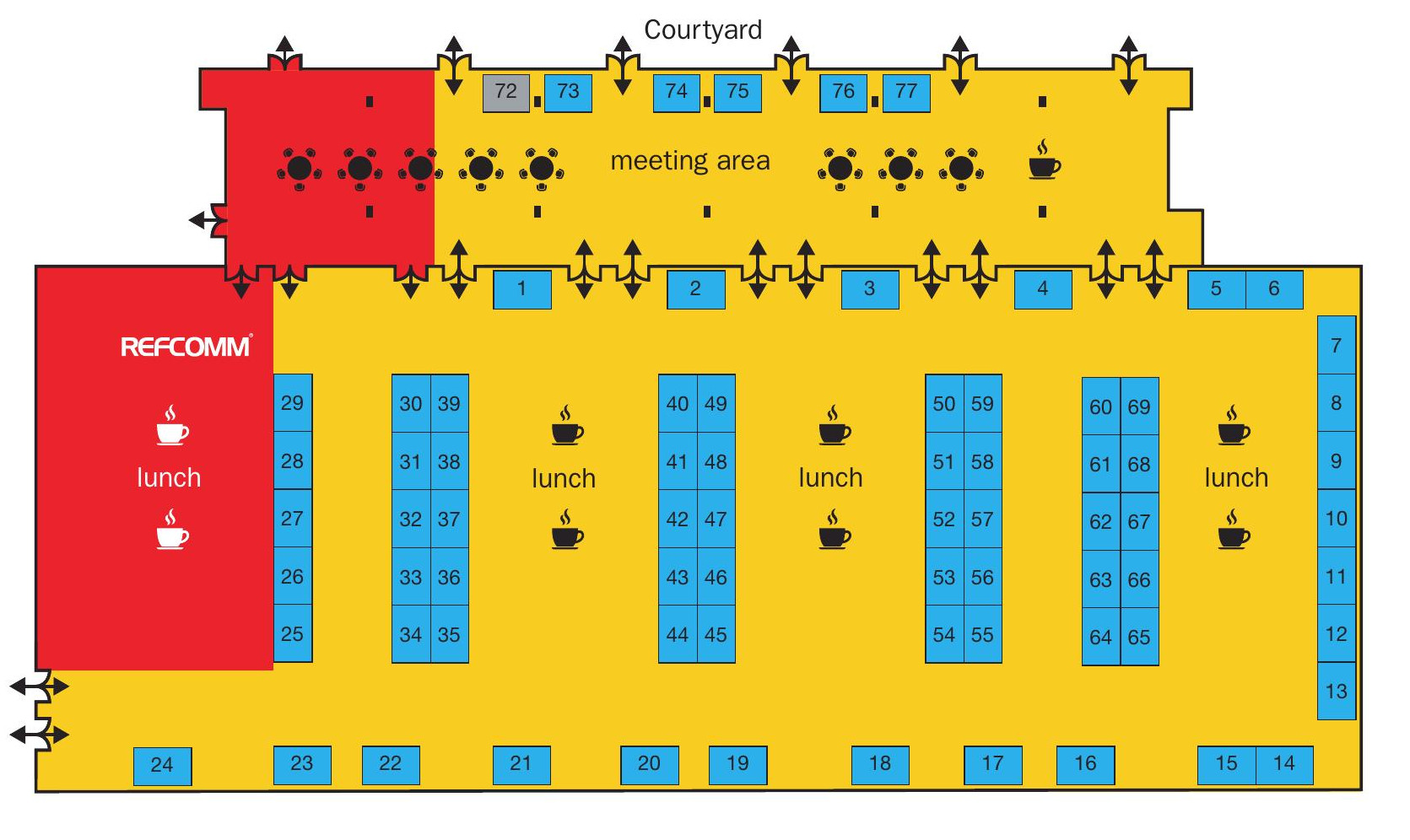

Exhibitor Floorplan

Exhibitor profiles

Running alongside the conference agenda there will be an exhibition of world-class solution providers serving the sulphur and sulphuric acid industries.

Academia Holtec Stand 12

Academia.Holtec is a leading provider of professional technical education programs, oriented mainly at the mining and chemical industry, offering a wide range of courses covering mining and plant operations, safety procedures, equipment maintenance, etc.Its asynchronous learning platforms for operations of metallurgical and sulphur burning sulphuric acid plant are based on 25 years of experience in the design, operation and maintenance of sulphuric acid plants.In general, its educational programs are orientated at keeping operators up to date in an ever-changing industry and aim to address the challenges related to renewal of labour force and transfer of knowledge, increased automation and incorporation of new technologies.

Aecometric Corporation Stand 17

For more than 50 years Aecometric has been a trusted name in providing industrial combustion equipment. The Aecometric High Intensity Burner technology stands alone in performance, quality and reliability. The Aecometric burner design lends itself perfectly to the combustion needs of the sulphur and sulphuric acid industry by providing maximum contaminant destruction, exceptional reliability and a high level of operational flexibility.

AGRU Kunststofftechnik Gesellschaft m.b.H. Stand 55

Founded in 1948, AGRU is one of the world‘s most important suppliers for high-quality piping systems, semi-finished products, concrete protection liners and lining systems made from thermoplastic materials. Especially the wide range of semi-finished products (PE, PP, PVDF, ECTFE, FEP and PFA) solves corrosion even in extreme applications.

Agruquero Stand 55

With more than 50 years of experience in the sector, Agruquero is a leading company in the distribution of thermoplastic products, such as double containment piping systems, storage tanks, valves for fluid conduction and process control, and ventilation, gas and odour washing systems.

Agruquero offers innovative and high-quality solutions that guarantee safety and efficiency in the storage, transportation and application of sulphuric acid and other chemical products for various industries.

AMETEK CSI Stand 36

CSI specialises in engineered products for sulphur recovery units and sulphur handling in liquid sulphur applications for sulphuric acid plants. In SRU applications, CSI provides engineered heating systems which meet the specific thermal requirements of SRU vapour and liquid lines and also sulphur storage tanks and vessels These applications use its industry known ControTrace and ControHeat products which eliminate cross-contamination, corrosion and plugging. For sulphur sealing, CSI is the only company that provides three choices for sulphur sealing: Seal legs, and two above-ground options: SxSeal 1000 (A first generation float style) and SxSeal 2000 (a second generation model with many advanced features). CSI is now introducing a new product system, ICOn, which is a revolutionary approach to sulphur degassing.

Anton Paar Stand 74

Anton Paar is the world leader in bench top density and concentration measurements and is now setting its sights on process analysis with the L-Dens, L-Com and L-Sonic sensors that measure in-line sulphuric acid density and concentration over the widest possible concentration ranges.

AWS Corporation Srl Stand 6

AWS Corporation provides solutions in several fields of industrial applications and pollution control, with the following product range:

- Aerosol, spray and mist separation (candle filter, vanes and meshpads)

- Air pollution control (WESP, venturi, DeNOx)

- Tower internals (liquid distributors, random/structured packing, trays, gas distribution inlet devices, etc.)

- Oil mist separators

- Sulphuric acid plant equipment

- Atomising nozzles technology

Axens Stand 30

Axens, an IFP Group company, provides a complete range of solutions for the conversion of oil and biomass to cleaner fuels, the production and purification of major petrochemical intermediates, the chemical recycling of plastics and all natural gas treatment and conversion options. The offer includes technologies, equipment, furnaces, modular units, catalysts, adsorbents and related services. Axens is ideally positioned to cover the entire value chain, from feasibility study to unit start-up and follow-up throughout the entire unit life cycle. This unique position ensures the highest level of performance with a reduced environmental footprint. Axens’ global offer is based on highly trained human resources, modern production facilities and an extended global network for industrial, technical supports and commercial services.

Ballestra S.p.A Stand 50

Ballestra S.p.A. is a multinational company specialising in engineering and contracting for chemical plants, covering both organic and inorganic chemistry. Ballestra offers advanced solutions for fertilizers, acids, surfactants, and detergents, ensuring expertise, flexibility, and reliability. Ballestra’s portfolio includes sulphuric acid and phosphoric acid technologies, a broad range of fertilizers, hydrofluoric acid and derivatives via Buss ChemTech. Ballestra offers its proprietary technologies as well as technologies licensed by its partners MECS, Prayon, and KVT. Its comprehensive services span from pilot tests to plant start-up, including feasibility studies, FEED, detailed engineering, procurement, construction management, field services, and aftersales support.

Exhibition Floorplans

BASF Corporation Stand 39

Since 1913 BASF has been running sulphuric acid production plants with the lowest SO2 -emission worldwide. BASF designs its catalysts for maximum outcomes. That starts with the unrivalled SO2 -emission performance they can deliver because of their large surface area. For its customers, that means effortless regulatory compliance, no additional emission reduction costs, higher conversion, and bigger profits. Because of their exceptional physical stability, BASF catalysts offer a longer lifetime, deliver energy savings, and minimise downtime risks. All of that comes with total service dedication, reliable customer support backed by the inventor of the sulphuric acid catalysts, and decades of experience.

Begg Cousland Envirotec Stand 47

Begg Cousland Envirotec, based in Scotland, has experience and technology that spans over 70 years in the field of sulphuric acid plant applications. With production sites in the UK, Italy, India and China (under licence), the company specialises in mist elimination equipment for sulphuric acid and fertilizer plants and innovates to optimise performance and maintenance. Meshpad demisters and fibre bed candle filters remove acid or other contaminants from process gas, and control stack emissions. In addition, Begg Cousland Envirotec makes state-of-the-art gas scrubbers, using rotating brush technology and phase separation meshes for tank venting duty and for abatement of chemical emissions.

Blasch Precision Ceramics Stand 19

Blasch’s unique and innovative ceramic systems provide significant process improvement benefits for SRUs. Blasch VectorWall™ for the reaction furnace and incinerator provide higher reliability, ammonia/BTEX destruction, faster installation, capacity increase, energy savings and lower emissions. Blasch ProLok™ ferrule designs require no castable refractory and offer far superior tube sheet and boiler tube protection preventing costly shutdowns.

Boldrocchi Stand 35

Boldrocchi is an international engineering and manufacturing firm with over 100 years experience, products in over 140 countries and offices worldwide. Its wide-ranging portfolio of solutions includes fans, blowers and compressors, heat exchangers and coolers, environmental solutions, noise protection, heavy-duty dampers & diverters and power generation/gas turbine ancillaries. Boldrocchi also offers an array of on-site services and provides turnkey projects.

The company portfolio includes sulphur recovery units using its API 672/617 compliant customised centrifugal compressors. These compressors, with pressure ratios of 1.5-14, are compact and low maintenance, offering lower operating costs and higher operating efficiencies. They, along with single and multi-stage blowers (with pressure rises up to 1 bar), are manufactured in Boldrocchi’s own Italian workshops with special alloys and steam traced casings for acid gas applications. They are then tested in-house at full speed, with motor power up to 7 MW. Boldrocchi’s systems can be found in several SRU projects worldwide, often with Claus/thermal reactors, offering a typical hydrogen sulphide conversion efficiency of 92-96%.

Christy Catalytics LLC Stand 62

Established in 1922, Christy Catalytics manufactures and supplies inert bed supports for fixed beds of catalyst and adsorbents as well as a complete range of tower packing to the chemical, petrochemical and refining industries worldwide.

For sulphuric acid customers, Christy Catalytics offers PROX-SVERS® ceramic balls for converter vessels; Christy® Pak ceramic saddles and Christy® Pak Cross Partition rings for absorption/drying towers as well as thermoplastic packing for gas cooling towers.

Clark Solutions Stand 4

Clark Solutions has been developing and producing equipment and disrupting technologies for the sulphur and sulphuric acid industries for over 30 years.

With thousands of installations in service, Clark Solutions is a leader in wire mesh and fiberbed mist eliminators, CSX coolers, piping and products and a whole range of state of the art technologies to enhance process performance and environmental compliance for sulphur and sulphuric acid operations.

Consultco Inc Stand 73

Consultco is an engineering firm that offers inspection and consultation services, based on years of hands-on experience in the manufacturing of non-metallic equipment such as FRP and Dual Laminate process piping and vessels.

Combining over 85 years of experience, and with multiple offices in Montréal, in the north of Milan and in Vancouver, Consultco relies on extensive technical and practical expertise in the manufacturing of equipment and uses a rigorous and constant inspection methodology to ensure monitoring of the evolution of the equipment. The chronological execution of the different inspection steps is used to provide an accurate diagnosis. The company is committed to integrating this experience along with an in-depth knowledge of ASTM, ASME, EN DIN, DT-15, BS, DIN and AWS standards.

Continental Industrie SAS Stand 20

Continental Industrie manufactures air/gas multistage centrifugal blowers up to 50,000 Nm3 /hr @ 1,5 bar. With more than 40 years of experience in research, development and manufacturing of centrifugal machines and with thousands of machines installed, its products provide proven reliability and confidence for continuous duty and extremely rugged service, 24/7. Continental Industrie is a leader in providing blowers for the oil and gas industry for combustion, desulphurisation, sulphur recovery, fluidisation, etc.

CS Combustion Solutions Stand 63

CS Combustion Solutions was founded by a team of senior specialists in the field of combustion technology. As a member of Unitherm-Cemcon Group which has been successfully dealing with burner, kiln- and furnace construction since 1946, CS can refer to Unitherm’s experience in boiler and rotary kiln burner construction. The CS Combustion Solutions team is experienced in engineering, supply and commissioning of vertical and horizontal burners and combustors for:

- Sulphur, spent acid and acid gas

- Waste gas and waste air

- Waste water

- Hazardous and special waste liquids

- Pasty waste fluids

- Burners and reaction furnaces for sulphur recovery units

Daltec Process Fans Stand 54

Daltec Process Fans is a designer and manufacturer of high quality industrial fans and blowers with an extensive product range from low volume high pressure to large volume low pressure. Daltec products are available in carbon steels, stainless steels, nickel alloys, aluminum, titanium, FRP or a combination to meet the specific demands of the application.

Damper Technology Ltd Stand 52

Damper Technology Limited (DTL) is an industrial damper manufacturer with over 50 years’ experience of providing custom damper solutions to industry worldwide. At the Sulphur + Sulphuric Acid 2024 exhibition DTL will be showcasing specially engineered dampers for applications involving process gases containing SO2 / SO3 .

Delta Controls Corporation Stand 7

Delta Controls Corporation is an internationally recognised expert in the design, engineering, manufacturing, and support of engineered process equipment and instrumentation. Delta Controls’ 50+ decades of instrumentation expertise allows it to provide innovative and quality solutions for demanding applications untouched by competitors.

Delta Controls offers three main product lines of temperature, level, and flow encompassing a variety of technologies including thermocouple, pyrometer, pressure, capacitance, mechanical, and more. All Delta products are manufactured to the extensive quality standards of its Louisiana based factory. Its temperature line ClausTemp™ , QSeal™ , ProSpection™ designs decrease maintenance and maximize uptime resulting in low costs. Delta’s products are in approximately 175 sulphur plants internationally including refineries, gas plants, upgrade facilities, sulphuric plants, and more.

Duiker Clean Technologies Stand 8

Duiker is a combustion engineering and contracting company, based in the Netherlands. The company has professional experience in designing, supplying and servicing sulphur recovery burners and a range of liquid and gaseous fuel burner systems and associated equipment for the petro-refining and petrochemical industries worldwide since the 1950s. Duiker products incorporate many typical features that improve overall plant performance and operation, safety and reliability.

Dütching Pumpen Maschinemfabrik GmbH & Co. Kg Stand 14

Düchting Pumps is a pump manufacturer with over 80 years of global experience in the field of advanced centrifugal pumps designed to achieve superior reliability and performance in corrosive and abrasive services. The company specialises in engineered pump solutions and aftermarket repair capabilities through its unique SICcast material technology, an engineered matrix of silicon carbide particles and epoxy resin binder that simultaneously combines 100% corrosion resistance and diamond-like abrasion protection. SICcast provides optimised protection against erosion-corrosion wear in phosphate fertilizer production across a wide range of challenging applications including phosphoric acid slurry, gypsum slurry, phosphate rock slurry, and much more.

EFC NV European Filter Corporation Stand 25

EFC NV is a Belgian based filtration technology supplier with over 25 years of experience. EFC NV offers a complete line of fibre bed mist eliminators and systems to abate liquid mist emissions. Its Atephos fibre bed mist eliminators, also referred to as fibre bed filters or candle filters, are optimal for removing sub-micron liquid aerosols from gas and air streams. EFC filters candles are innovative due to the variable bed densities technology offering its customers a wide range of possibilities to optimise their filtration process by increasing the efficiency, reducing the operational costs or to save on capital investment costs.

Besides liquid and air filtration, EFC NV has its own specialised oil filtration division and also provides technology and innovation to give pure air and pure liquid.

Fluor Stand 18

Fluor Corporation is one of the world’s leading engineering, procurement, construction, maintenance, and project management companies. Its unique experience and knowledge in the design of sulphur recovery plants, tail gas treating units, and proprietary process technologies, provides a wide range of proven and innovative solutions for its clients. With over a century of experience in handling complex projects in challenging locations, Fluor’s dependability, expertise, and safety record distinguishes it as a respected leader in sulphur recovery.

FluoroSeal Stand 45

For over 40 years, FluoroSeal has been manufacturing and customising a wide range of valves for various industries. At Sulphur + Sulphuric Acid 2024, FluoroSeal will be displaying valves applicable for sulphur and sulphuric acid applications including jacketed sleeved plug valves, PFA lined plug valves, and GF2P/ PFA lined butterfly valves.

Glatt Ingenieurtechnik GmbH Stand 10

Glatt Process Technology Food, Feed & Fine Chemicals provides product, technology, and system expertise for the entire value chain, from particle design to industrial production. The company focusses on powder synthesis and fluidised bed processes for developing, manufacturing, optimising, and refining powders and bulk materials such as granulates and pellets.

Gouda Refractories BV Stand 1

Gouda Refractories BV, established in 1901, serves all primary industries, providing worldwide customer specific refractory solutions, added value with in-house design, manufacturing of high grade/ alumina refractory linings (bricks, monolithics, precast shapes), supervision/ installation services. Acquainted with the processes, Gouda Refractories co-operates with oil companies, refineries, chemical plants, licensors, engineering companies and has a proven track record within the SRU market.

HEC -High Efficiency Combustion Technologies Stand 58

HEC is a global supplier specialising in burners and associated combustion equipment accessories for sulphur recovery installations ranging from 1 t/d to over 12,000 t/d+ capacities. Applications include custom engineered burners for reaction furnace, RGG/SCOT/reheat/Superclaus and tail gas incineration systems. CFD analysis is utilised for troubleshooting / root cause analysis, and extensively for product development and refinement. HEC offers RF expertise for challenging applications involving; high level oxygen enrichment, high turndown, very lean feed and rich feed acid gas processing, high content hydrocarbon (BTX) and ammonia destruction and more. HEC technical publications on a variety of topics related to SRU recovery technology are available upon request.

Howden, a Chart Industries Company Stand 29

Howden specialises in the design, application and manufacture of customised turbo blowers and compressors for both sulphur production and recovery applications. As the leading global supplier, Howden draws on its extensive experience from its trusted product brands as well as working closely with customers to offer a unique range of mutually compatible compressors and drivers.

In addition, Howden offers robust and reliable steam turbines for power generation or as mechanical drive, for example, for waste heat utilisation in sulphur and sulphuric acid plants.

Hubei Sanfeng Turbine Equipment Co., Ltd Stand 56

Hubei Sanfeng Turbine Equipment Co., Ltd. (founded in 1958) is a modern high-end equipment manufacturing enterprise specialised in the research and development, design and manufacturing, system consulting and service of blowers, compressors and fans. Today the company has a 300,000 sqm production facility with approximately 700 employees and thousands of production equipment of various types.

HUGO PETERSEN Stand 44

HUGO PETERSEN’s technology portfolio for sulphuric acid ranges from the production of high-quality sulphuric acid and oleum from elementary sulphur, metallurgical off-gas and spent gases.

In addition, HUGO PETERSEN is known for its expertise in hydrochloric acid and gas cleaning, where wet, dry and catalytic processes are being applied. The company also offers consulting, design and construction of new plants and plant units, as well as the revamping and refurbishing of existing plants.

Industrial Ceramics Ltd Stand 69

For over 60 years, Industrial Ceramics Ltd has been a leading manufacturer and supplier of custom shaped refractory ceramics for use in the petrochemical and sulphur industries worldwide.

The company specialises in the design and manufacture of ceramic ferrules and inserts for the thermal protection of waste heat boilers, as well as nozzles and shapes for specialised applications. Specifically, the company is world renowned for the popular 2-piece Hexagon Head ferrule as well as its solid hexagon head design. With over 60 years’ experience, Industrial Ceramics Ltd is trusted for its superior technical expertise and product reliability related to its customers’ refractory needs.

IPCO Stand 32

IPCO is a world leader in sulphur processing and handling solutions, and has delivered complete end-to-end systems to hundreds of companies around the globe since 1951.

Two systems are available to meet all throughput requirements: For small to medium capacity requirements, IPCO’s well-known Rotoform® technology offers excellent product uniformity and environmentally friendly operation. The efficiency of this single step, liquid-to-solid process results in a premium quality product. The uniform shape and size of Rotoform pastilles makes them free-flowing for easy handling, while a predictable high bulk density is a major advantage in terms of storage and transportation. With more than 700 Rotoform pastillation systems installed to date, Rotoform remains the world’s most widely used process for the production of premium quality pastilles.

For medium to high capacity requirements, IPCO’s fully automated drum granulation system uses rotating drum technology to deliver high productivity “once through” performance. This is the highest capacity granulation unit available in the industry and delivers a uniform end product of a definable size. Other key benefits include low maintenance and continuous operation for high availability.

IPCO’s newest drum granulator SG20 has been commissioned in Italy and serves as a global showcase for this patented system. Prospective customers are invited to visit the site and assess the system in operation.

ITT RHEINHÜTTE Pumpen GmbH Stand 68

ITT RHEINHÜTTE Pumpen GmbH offers chemical, petrochemical, fertilizer and related industries a full range of vertical and horizontal pumps in metal, plastic, and ceramic materials.

RHEINHÜTTE Pumpen designs and manufactures safe and efficient pumping solutions for even the most difficult applications. An expert in corrosion and wear resistance, RHEINHÜTTE Pumpen leads the field with highly sophisticated know-how in many specific areas. The company specialises in chemically resistant centrifugal and axial flow pumps for handling molten suphur, sulphuric acid, and phosphoric acid.

J. Rettenmaier & Söhne Stand 41

JRS is the world’s leading producer of precoat filter aids that replace minerals such as diatomite and perlite in the filtration of molten sulphur. FILTRACEL filter aids offer the following benefits: significantly lower process costs, longer filter cycles, reduced filter aid consumption, less waste and less sulphur loss, longer lifetime of filter elements, no catalyst poisoning.

JL Goslar GmbH Stand 16

JL Goslar, an expert in the processing of lead, tin and their alloys, has a portfolio which includes the following products and services:

- Wet electrostatic precipitators

- Star tube cooler bundles

- Spare parts for wet electrostatic precipitators

- Lead lined vessels and tanks

- Autoclaves

- Lead linings on site

- Assemblies on site

KALFRISA S.A.U. Stand 34

KALFRISA S.A.U. is a Spanish family-owned engineering company with almost 60 years of experience in delivering advanced technological solutions for energy efficiency and environmental protection in industrial applications.

KALFRISA offers cutting-edge preheaters for sulphuric acid production, ensuring smooth start-up and optimal plant operation. Its start-up heaters, provide the converter with the necessary heat to reach the exothermic temperature required for catalytic conversion, crucial for the process.

KALFRISA’s preheaters enhances plant reliability, flexibility and efficiency by leveraging state-of-the-art burner management units, latest automated control systems and remote support based on IoT solutions.

Kanzler Verfahrenstechnik GmbH Stand 51

Kanzler Verfahrenstechnik GmbH (KVT) is a global engineering and technology company offering a full range of services from the initial concept to a turnkey industrial process plant commissioning. KVT’s technology portfolio for wet sulphuric acid – OXYSULF comprises 360° solutions for the recovery, regeneration and production of sulphuric acid from various types of off-gases, spent acid or sulphur burning. The OXYSULF process is based on wet-catalytic oxidation of sulphur bearing compounds with recovery of concentrated sulphuric acid. A smart tail gas treatment system allows to reach exceptional high sulphur conversation rate and guaranteed low SO2 emissions at stack.

Kimre Stand 48

Kimre™ high-performance, interlaced mesh structure has provided revolutionary air pollution control and fluid separation products since 1973. Kimre™ technology is proven to economically meet the toughest applications at any gas flow rate, for horizontal or vertical flow. Proven applications in phosphate fertilizer plants include:

- Phosphoric acid production

- Ammonium phosphate and NPK production

- Animal feed ingredients production

- Super phosphate production

- Sulphuric acid production

- Rock production

Kimre™ Technology includes: B-GON® mist/fume eliminators, Kimre™ CANDLE fiber-bed coalescing filters, KON-TANE® scrubber tower packing, SXF™ semi-cross-flow contactors, AEROSEP® multistage aerosol separation, Kimre™ Technology; scrubber/mass transfer equipment; DRIFTOR® drift eliminators and LIQUI-NOMIX® liquid/liquid separation.

Knight Material Technologies Stand 22

Founded in 1910, Knight Material Technologies (KMT), Canton, OH, (formerly Koch-Knight) designs, manufactures, installs, and services acid-resistant linings for vessels/towers in the sulphuric acid industry worldwide. KMT produces industry-leading brick, mortars, PYROFLEX® membranes, internals, FLEXERAMIC® structured and random packing media. Subsidiaries Electro Chemical and Superior Dual Laminate Products specialise in fluoropolymer lining for the chemical processing industries.

Lanexis Stand 5

Lanexis is a specialised acid resistant lining and refractory company. For sulphuric acid and phosphoric acid plants the company supplies anti-acid carbon bricks, silica bricks, specialised graphite filled membranes, mortars, grid bars, high strength grid blocks, high alumina refractories and refractory coatings with a focus on CO2 reduction & reducing heat losses.

Lechler GmbH Stand 9

Lechler is Europe’s no. 1 and one of the world’s leading manufacturers of precision spray nozzles and systems for over 140 years, for all industrial applications with more than 700 employees worldwide. The company headquarters are located in Germany, and there are 14 subsidiary companies which are part of the worldwide Lechler group.

Matrix Service Company Stand 43

Matrix Service Company, through its subsidiaries, is a global leader in sulphur recovery, processing, storage, and handling. Technologies include proprietary Devco II prilling, high capacity sulphur melting, material handling, and sulphur block pouring. Its design and execution expertise include the world’s largest sulphur melting facility, as well as sulphur forming facilities in the United States, Canada, Saudi Arabia, China, and elsewhere.

Messer Stand 60

Messer is the world’s largest privately-held industrial gases company, with unrivalled technical development capabilities and agility from people you know and trust. Messer sustainably grows and innovates with its chemical and energy customers with gases application technologies that boost throughput and lower their carbon footprint.

Metso Stand 21

Metso is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally.

With over 650 sulphuric acid plant installations worldwide, Metso’s Metals and Chemical Processing business line is a leader in sulphuric acid plant design and delivery. The portfolio includes plants based on elemental sulphur combustion and metallurgical off-gas handling, as well as plants for special processes such as the thermal decomposition of iron sulphate and spent sulphuric acid. These are complemented by processes for the production of liquid SO2 and SO3 , various concentrations of oleum, and special high-grade sulphuric acid.

The Metso Edmeston Product Center specialises in the design and supply of strong acid equipment, mainly manufactured from the proprietary alloy Edmeston SX® . Edmeston SX® stainless steel was introduced to the market in 1984 and is characterised by an excellent corrosion resistance over a wide concentration range of sulfuric acid at high temperatures.

NORAM Engineering and Constructors Ltd Stand 59

NORAM designs and supplies equipment and technologies for the process and resource industries. For sulphuric acid clients, NORAM offers improved equipment including sulphur furnaces, stainless steel converters, radial and split flow gas exchangers, ducting and expansion joints, acid towers (traditional brick-lined and NORAM SX® alloy as well as HP™ packing), and other NORAM SX® components including, acid valves, acid distributors (trough and Smart™ ), piping and acid coolers. NORAM also offers debottlenecking and emission reduction studies. NORAM is a specialist at refurbishing existing acid plants with enhanced equipment to make them run better.

Nuberg Industries Ltd Stand 77

Nuberg EPC is a global EPC and turnkey project management company, providing end-to-end solutions for plant engineering & construction. With 65+ projects across 32 countries, Nuberg specialises in fertilizers, chemicals, hydrocarbons, and green energy.

Nuberg has successfully executed over 20 LSTK sulphur projects worldwide, including key projects like NPK fertilizer, sulphuric acid, sulphur recovery unit (SRU), and sulphur bentonite in Saudi Arabia, Egypt, Ethiopia, India, Turkey, and more. Highlights include 500 t/d and 300 t/d sulphuric acid plants in Egypt and a 550 t/d sulphuric acid unit modernisation in the Czech Republic, reinforcing its global leadership in sulphur-related EPC projects.

Ohio Lumex Stand 13

Specialising in monitoring solutions for industrial applications for 25+ years, Ohio Lumex is excited to bring its expertise to the sulphuric acid industry with the introduction of the Ei4200 Dew Point Monitor for instant leak detection and dew point measurement.

Combining cutting-edge technology, application expertise, and a culture of service excellence, Ohio Lumex offers a full array of tools to meet our customers’ unique requirements. From analytical instruments, to laboratory services, to onsite testing, Ohio Lumex aims to provide comprehensive solutions to industry needs.

OHL Gutermuth Industrial Valves GmbH Stand 28

OHL Gutermuth has been making valves for more than 100 years. Control and shut off valves from OHL Gutermuth are the right choice when it comes to regulating the flow of gases, vapours, liquids and granulates in a safe and economic way.

Special projects such as desulphurisation Claus and tail gas treatment units, sulphuric acid plants, methanol plants, concentrated solar power, steelworks and shipbuilding are supplied with various valve designs.

Optimized Gas Treating, Inc Stand 33

SulphurPro® is best in class simulation software for sulphur recovery units (SRUs). SulphurPro is based 100% on fundamental reaction kinetics and sound heat transfer models that allow all aspects of the SRU to be accurately predicted. SulphurPro SRU simulations can be seamlessly integrated into ProTreat® , a 100% rate-based simulation tool, for a full assessment of the complete sulphur recovery system including AGRU, AGE, SWS, SRU, and TGTU.

P & P Industries AG Stand 65

P & P Industries is dedicated to achieving sustainable industrial solutions. Its expertise lies in green technology for a cleaner industry. With over 20 years of global experience, the company offers a range of products and plant systems for waste gas treatment, sulphuric acid technology, precious metal catalysts as well as comprehensive engineering solutions.

P & P Industries’ track record of delivering customised and sustainable solutions sets it apart with its success underpinned by its competence, entrepreneurial spirit, and profound passion for ecotechnological advancements.

PegasusTSI Inc Stand 11

PegasusTSI, Inc. (PegasusTSI) is a privately owned company delivering engineering, procurement, and construction management (EPCm) services worldwide. With over 40 years of expertise, PegasusTSI has built a strong reputation in the implementation of sulphur and sulphuric acid technologies. Its experience involves sulphur handling, storage, and transportation, sulphur burner systems, waste heat boilers, heat recovery systems (HRS), and sulphuric acid plant converter replacement. PegasusTSI has successfully managed numerous complex projects in these areas, providing innovative solutions for established industry leaders and new start-ups

QMAX Industries, LLC Stand 15

Since 2010, QMax has been a leading manufacturer and designer of modern pipe tracing and tank heating equipment. The company’s streamlined approach to implementing heating systems, using its innovative products, makes QMax the best solution for pipe and tank heating. QMax commits to simplifying your project with an effective heating solution with every BTU in mind.

REMA TIP TOP Stand 26

REMA TIP TOP manufactures rubber adhesives, repair materials, pulley lagging and industrial rubber products for wear and corrosion protection; providing expert factory and field installation of rubber linings, tankage corrosion linings, and wear linings. The company helps its customers prevent, reduce or repair wear caused by abrasion or corrosion.

SBS Steel Belt Systems Stand 57

SBS Steel Belt Systems manufactures, installs and commissions continuous machinery and plants equipped with stainless steel belts for chemical, petrochemical, fertilizer, sulphur, food, rubber and powder coating industries. The most advanced techniques in the industrial fields have led SBS to work for the best European, American and Asian companies, as well as for the most important engineering groups. SBS is able to offer complete packages, starting from the design, through the construction, the installation, the commissioning up to the after sales service of their machinery. The company is part of the international group Berndorf Band GmbH / Austria, provider of stainless steel belts.

Schenk Stahl GmbH Stand 76

Schenk Stahl was founded in 1986 by the Schenk family as a trading company selling stainless steel and heat-resistant stainless steel products from its main office in Vienna. After opening a warehouse in Dusseldorf-Heerdt in 1989 the company started to tailor the company’s own product range to customer requirements. For over 40 years the company’s business has revolved around stainless steel quality pipes, specialising in heat-resistant materials, especially pipes in welded and seamless design. Its customers can be found throughout Germany and its neighbouring countries, in Eastern Europe and Turkey, in India, the USA and the United Arab Emirates.

SENSIA Solutions Stand 24

SENSIA Solutions is a leading company in the infrared imaging market with systems operating worldwide. SENSIA’s RedLook solution uses comprehensive optical gas imaging technology designed for 24/7 automatic operation and real-time gas detection in multiple applications. RedLook’s continuous monitoring technology combines computer vision and artificial intelligence to provide automated real-time classification and information on everything of interest to their customers, such as gas detection alarms and gas leak flow rates, the combustion efficiency of flares, early flame detection alarms, monitoring temperature levels of critical components, or controlling intrusions into forbidden areas.

SensoTech Stand 53

SensoTech manufactures analysers for concentration measurement of sulphuric acid and oleum in various applications. The LiquiSonic® sensor technology is based on sonic velocity measurement providing an accuracy of up to 0.03 wt-%. SensoTech offers both inline sensors measuring the sulphuric acid strength directly in pipes or vessels, and laboratory systems. The analysers are robust, maintenance-free and made in Germany. The LiquiSonic® controller displays the concentration values and transfers the real-time information online to process control systems.

Shandong Junfei Environmental Protection Technology Co., Ltd St. 37

Shandong Junfei is the new player in the SRU catalyst market. With over 30 years of experience in manufacturing high-quality catalysts, the company has built a reputation for providing high-activity catalysts with over 6 models. Shandong Junfei is committed to providing excellent service and customised solutions for global clients.

Sharplex Filters (India) Pvt. Ltd. Stand 27

Sharplex Filters (India) Pvt. Ltd. Is a company with experience in molten sulphur filtration having supplied more than 60 filters in sulphuric acid and sulphonation plants worldwide. Sharplex offers horizontal pressure leaf filters for molten sulphur filtration in shell retraction or bundle retraction design. Sharplex also manufactures and supplies polishing cartridge filters for molten sulphur filtration. Sharplex is strong in design, engineering, manufacturing and supplies filters with ASME, Merkblatter codes as well as PED certifications. Filter screens for molten sulphur filters are a 5 layer design with strong backing screens. Rigidrain backing screens can also be provided for screens.

Smart SCOPE GmbH Stand 61

Smart SCOPE is a provider of engineering services for sulphric acid and industrial gas cleaning plants. With its innovative concepts Smart SCOPE addresses the specific needs and challenges of its customers and develops tailor made solutions for them. Focusing on plant revamps and optimisation Smart SCOPE identifies ways to maximise plant performance and provide process and equipment design for reliable operation. The experience of its engineers in plant design and operation is the key to identify the potential of each individual plant in a flexible and smart way.

STEULER-KCH GmbH Stand 61

Steuler Linings is a complete service provider for surface protection and acid proof /refractory linings in sulphuric acid and gas cleaning plants. Its Plastic Linings division also offers bundles in WESP, apparatus- and piping construction. Steuler Linings is a provider for almost every type of engineering, material supply, installation, repair and maintenance.

Sulphurnet Stand 42

Sulphurnet focuses its activities on the design and manufacturing of equipment for sulphur processing plants. The company offers engineering services and suppies proprietary equipment.For the sulphuric acid industry, Sulphurnet provides complete solutions, where it designs the entire sulphur melting and filtration process, from solid feed to liquid sulphur storage tanks.

Sulphurnet is also a provider of solutions to purify sulphur waste streams to make them suitable for sulphur forming and commercial trade. The company also uses state of the art techniques to offer its clients environmental solutions such as gas cleaning systems for sulphur melting and filtration plants.

Sulzer Stand 46

Sulzer, with 180 years of experience in developing pumping solutions for production processes involving corrosive or abrasive media, adds value to its customers’ processes through best-inclass products and services. As Sulzer and Ensival-Moret have joined forces, the company is now able to offer an even deeper process understanding for demanding applications.

Sulzer offers a complete range of horizontal and vertical pumps, as well as agitators, tailor-made to satisfy the customer specifications for molten sulphur and sulphuric acid. Its solutions cover various applications of the petrochemical, chemical, fertilizer and metal industries. Advanced design and materials, a wide range of shaft seals and sealing systems, and the overall operating efficiency ensure a reliable process and a maintenance-free operation.

Teknokon Group Stand 31

Teknokon Grup companies provide services to a wide range of customers, which include sulphuric acid plants, chemical plants, mineral processing and refining plants, petrochemicals, power plants, oil refineries, petroleum and gas storage facilities, air separation plants, food & beverage plants, and iron & steel plants.

With its multi-disciplinary structure that includes individually specialised companies, Teknokon Grup plays an active role in all stages of industrial facilities and projects: from engineering to commissioning, and later followed by maintenance. The Group gathers all of its services under a single roof, allowing its customers to easily get support and access streamlined project management tools, while leading the market with its 360° approach that includes all components

Topsoe Stand 40

Topsoe is a global leader in development and supply of technologies, catalysts and services for the sulphur and sulphuric acid industry. With its Smarter Sulfur Solutions portfolio, Topsoe works to ensure that its customers enjoy the benefits of a highly efficient and reliable solution while complying to the most stringent emission requirements. Its high-activity catalysts enable higher conversion and energy efficiency, while simultaneously reducing pressure drop and improving production stability.

Voovio Technologies SL Stand 66

Voovio is a global deep tech company, headquartered in Houston (US) and Madrid (Spain). Founded by a group of experts in machine vision, industrial R&D and automation, Voovio was created to make the process industry more efficient, more profitable, environmentally friendly and safer using proprietary enhanced reality technology.

WEIR Stand 3

The Weir Minerals range of Lewis® pumps and valves are made with Lewmet® alloys to provide superior erosion resistance and corrosion protection. Lewmet® nickel-chrome alloy is engineered to withstand long-term exposure in the harsh operating environment of contact process sulphuric acid plants. The company’s continuous research, development and innovation mean that it is constantly improving performance, extending wear life, simplifying maintenance practices and delivering the lowest total cost of ownership to its customers. The company prides itself on its ability to work closely with its customers and build long-term relationships.

WIKA Stand 2

The WIKA group is a worldwide leader in pressure, temperature, level, force and flow measurement, as well as calibration technology. Founded in 1946, WIKA is today a strong and reliable partner for all the requirements of industrial measurement technology, thanks to a broad portfolio of high-precision instruments and comprehensive services.

Worley Chemetics Stand 49

Worley Chemetics is a leading provider of technology, solutions and equipment fabrication for sulphuric acid, chlorine chemicals and other specialty chemical facilities.

Since 1964, it has been servicing worldwide customers in the chemical, oil and gas, fertilizer, pulp and paper industries with specialised design and fabrication of proprietary and non-proprietary equipment, engineered systems and plants. Its technology helps its customers to achieve higher capacities and reliability, lower their operating costs, substantially decrease emissions, improve safety and maximize long-term profits.

With its CORE-SO2™ sulphuric acid plant technology Worley Chemetics unlocks green fertilizer and sustainability goals across industries. By leveraging co-produced oxygen from water electrolysis and green ammonia, CORE-SO2™ decreases acid plants’ environmental footprint and greenhouse gas emissions, recovers CO2 -free electrical power and enhances profitability. Its small physical size confers significant construction advantages, while low internal gas flows and fewer pieces of equipment enable modularisation.

Worley Comprimo Stand 49

Worley Comprimo is a global provider of gas treating and sulphur recovery technology focused on reducing emissions, increasing site reliability and improving plant economics. For over 60 years, its technology has been at the forefront of sulphur recovery, featuring in more than 1,200 sulphur recovery units worldwide.

Worley Comprimo’s portfolio covers the full range of technologies in gas treatment, sour water stripping, sulphur recovery, sulphur degassing and sulphur handling, storage and transportation. Through its desulphurisation and carbon capture technologies, it helps its customers to reduce emissions of SO2 and CO2 , shaping the future of sustainability in this industry.

Wylton (China) Chemical Co., Ltd Stand 23

Wylton (China) is proud to be known as the pioneer that significantly influenced the development of the sulphuric acid industry in China, by offering integrated services to sulphuric acid plants worldwide: Technical process design participation, project construction management, equipment and spares supply, catalyst supply and screening, operators training, start-up/commissioning service, maintenance and overhaul, full management of acid plant etc.

As the largest privately owned sulfuric acid producer and the largest market-share holder of sulphuric acid catalyst in China, Wylton is eager to establish a long term good cooperation partner relationship with all clients from all over the world.

Zeeco Stand 67

Founded in 1979, Zeeco has steadily become the world leader in designing and manufacturing advanced combustion and environmental solutions. Headquartered in Tulsa, Oklahoma, USA, Zeeco is a privately held business with more than 2,500 employees and 30+ global locations. The company executes 10,000+ projects yearly for refining, production, petrochemical, LNG, power, pharmaceutical, biogas, and other industries. ZEECO® products and solutions include ultra-low-NOx burners, flare systems, thermal oxidizers, vapor control, rentals, aftermarket solutions, global field services, and combustion electronics.

Zeeco’s comprehensive offering helps customers reduce emissions, optimize processes, and maximise operating efficiency while meeting global environmental compliance requirements. Zeeco also operates the world’s largest combustion research and test facility and a manufacturing facility on a 250-acre campus at its Global Technology Center in Broken Arrow, Oklahoma, USA.